+86-13349293098

+86-13349293098 Top Three Stage Hydraulic Cylinder Suppliers and Factories for Reliable Solutions

When in need of efficient and reliable Three Stage Hydraulic Cylinders, selecting a dependable supplier is crucial. At Hefei King Slewing Bearing Technology Co., Ltd., we provide custom solutions tailored to your specific requirements. Our team specializes in manufacturing high-quality hydraulic cylinders suitable for a wide range of industrial applications. We are committed to delivering durable and efficient products, working closely with clients to achieve their unique goals. With advanced technology and a skilled engineering team, we focus on producing exceptional hydraulic solutions. Reach out to discuss how our custom Three Stage Hydraulic Cylinders can enhance your operational efficiency. Quality, reliability, and dedicated support await you!Why Choose Three Stage Hydraulic Cylinder Factory Manufacturer

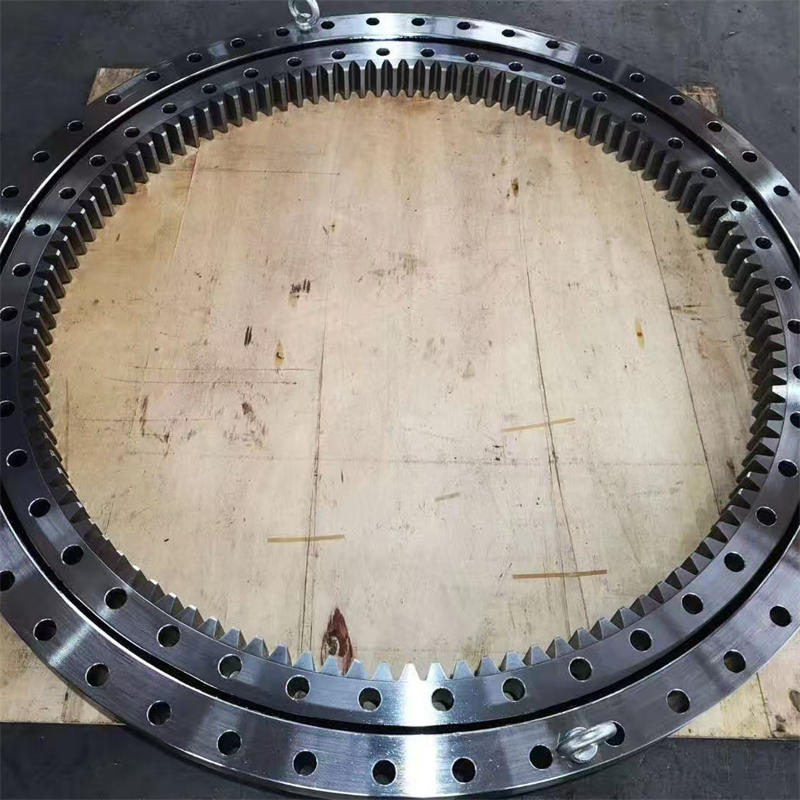

When it comes to sourcing high-quality hydraulic cylinders, Hefei King Slewing Bearing Technology Co., Ltd. stands out as a premier manufacturer and exporter. Located in the heart of Hefei City, Anhui Province, China, our company specializes in producing not only top-tier excavator Slewing Rings but also a comprehensive range of hydraulic cylinders tailored to meet diverse industry needs. With years of experience and a commitment to excellence, we are dedicated to delivering products that ensure performance and reliability. Choosing a factory manufacturer for your hydraulic cylinder needs involves several considerations, and Hefei King is positioned to meet them all. Our state-of-the-art facility is equipped with advanced machinery and technology, allowing us to maintain strict quality control throughout the manufacturing process. We understand the importance of durability and efficiency in hydraulic applications, which is why we utilize only the highest quality materials to produce our cylinders. Additionally, our team of skilled engineers and technicians continuously innovates, ensuring that our products meet global standards and exceed customer expectations. Furthermore, partnering with Hefei King means entering a robust support system for your procurement process. We pride ourselves on our ability to provide customized solutions that cater to specific requirements, backed by reliable after-sales support to guarantee customer satisfaction. By choosing our factory, you are not just purchasing hydraulic cylinders; you are securing a strategic ally in your supply chain. Trust Hefei King Slewing Bearing Technology Co., Ltd. to deliver quality, reliability, and exceptional service, elevating your projects to new heights.

Why Choose Three Stage Hydraulic Cylinder Factory Manufacturer

| Feature | Description | Benefit |

|---|---|---|

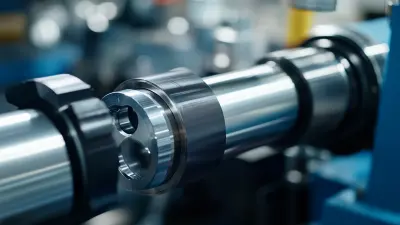

| High Precision | Manufactured with CNC technology for tight tolerances | Improved operational efficiency and reduced wear |

| Durable Materials | Use of high-strength steel and corrosion-resistant coatings | Extended lifespan and lower maintenance costs |

| Customization Options | Various bore diameters and stroke lengths available | Tailored solutions to meet specific application needs |

| Quality Assurance | Rigorous testing and quality control processes | Reliability and performance you can count on |

| Technical Support | Expert consultation and assistance available | Informed decisions and optimized performance |