+86-13349293098

+86-13349293098

01

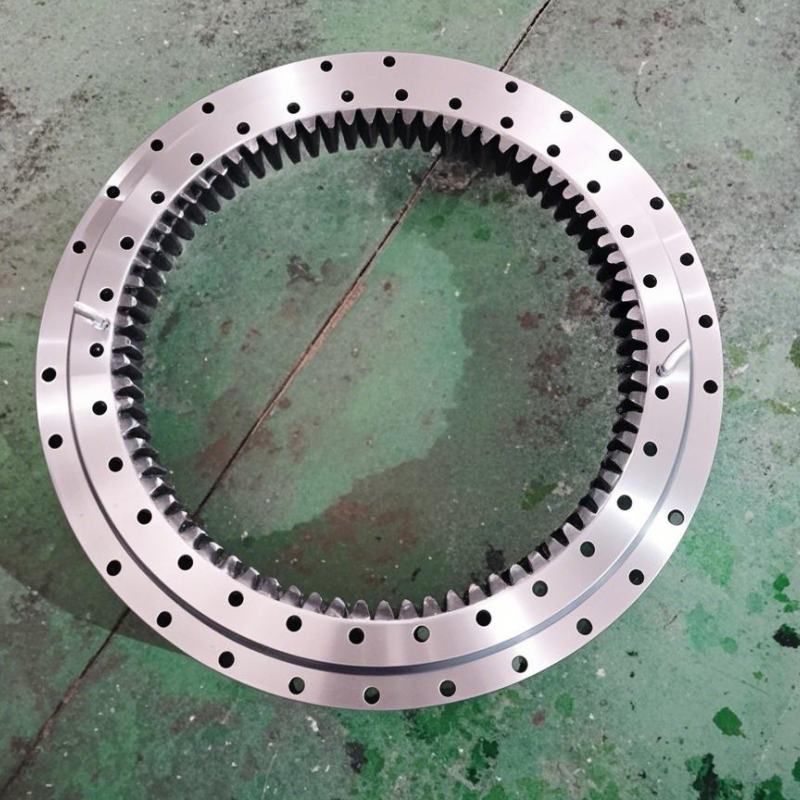

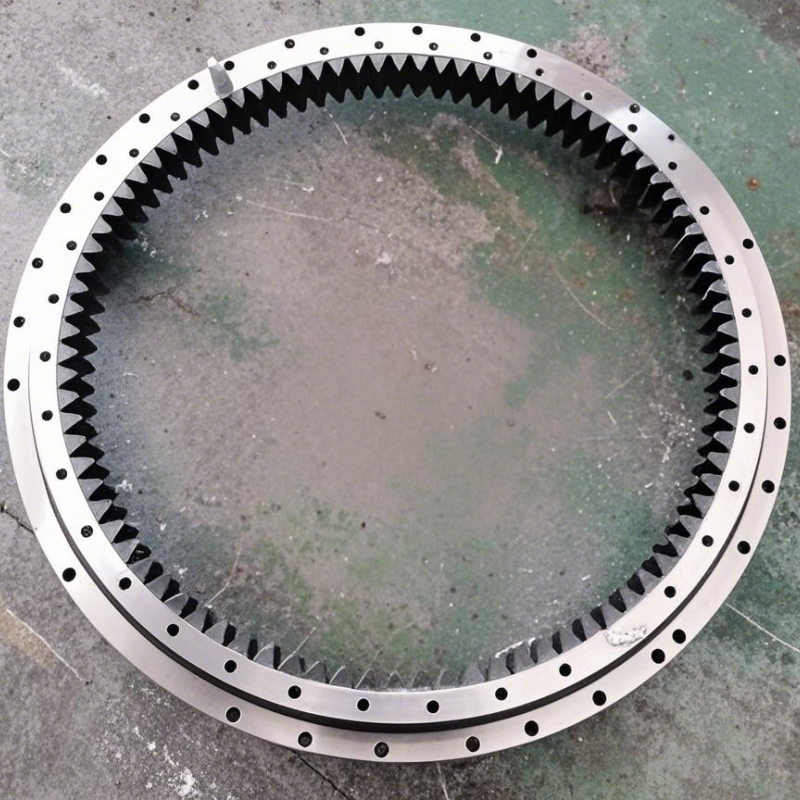

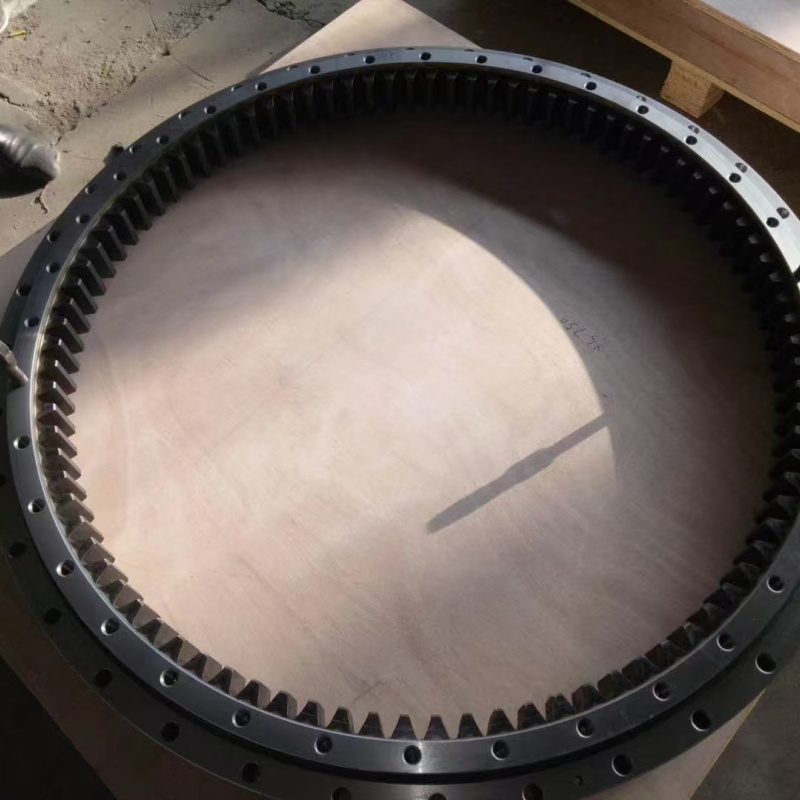

SK230-6 Slewing Circle LQ40F00004F1 Kobelco Excavator

Why choose us

-

Product Excellence

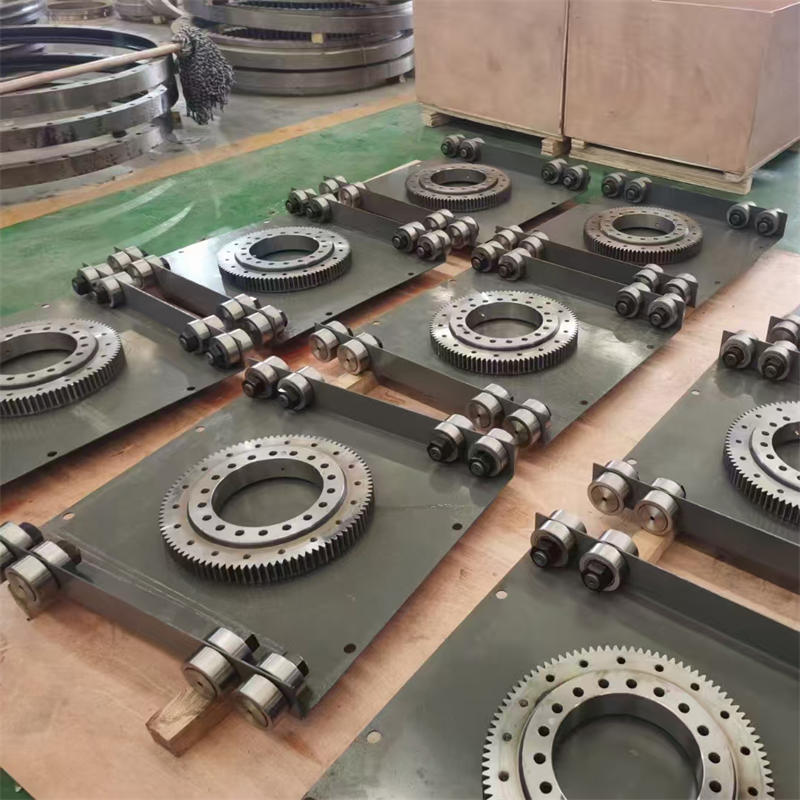

Our focus is firmly centered on excavator slewing rings. With an expansive production capacity, we can produce over 1,000 different part numbers. Each of these products is painstakingly engineered to be fully compatible with leading excavator brands worldwide, such as CATERPILLAR, KOMATSU, HITACHI, KOBELCO, HYUNDAI, VOLVO, DOOSAN, LIEBHERR, DAEWOO, JCB, CASE, SUMITOMO, and KATO. This wide - ranging product portfolio enables us to satisfy the diverse requirements of customers across various industries and geographical locations. -

Technical Prowess

Our engineering team, with more than 20 years of in - depth experience in excavator slewing ring R&D, forms the backbone of our innovation capabilities. Paired with a professional measuring team, we offer a one - of - a - kind service. We are able to send our experts directly to customers' job sites to precisely measure old or damaged slewing rings. This on - site measurement service guarantees that the replacement parts we produce are an exact fit, minimizing equipment downtime and maximizing operational efficiency.

Company Introduction

At Hefei King Slewing Bearing Technology Co., Ltd., we are not just a manufacturer and exporter; we are a partner dedicated to providing outstanding products and services. We look forward to collaborating with customers around the world, helping them enhance the performance and longevity of their excavators and cranes with our superior slewing bearings.

Product Model List

|

Kobelco |

|||

| Excavator model number | Part number | Excavator model number | Part number |

| SK60-3 | 2425U232F1 | SK210LC-6 | Yn40F00004f1 |

| SK75-8 | YT40F00004F1 | SK210LC-8 | YN40F00026F1 |

| SK75 UR-3 | 2425U261F1 | SK220LC III/IV | 24100N7441F1 |

| SK130LC IV | LP40FU0001F1 | SK230-6 | LQ40F00004F1 |

| SK135SR | YW40F00001F1 | SK235 | YN40F01004P1 |

| SK-140 | YY40F00009F1 | SK250-6E | LQ40F00005F1 |

| SK140SR | YY40F00009F1 | SK250-8 | LQ40F00014F1 |

| SK200 | 24100N7440F1 | SK250LC-6E | LQ40F00004f1 |

| K907LC-2 | 24100N3978F | SK250NLC-6 | 24100N7441F1 |

| SK907-2 | 24100N3978F2 | SK260-8 | LQ40F000014F1 |

| SK200 | YN40FU0001F1 | SK260LC-8 | LQ40F00014F |

| SK200-3 | 24100N440F1 | SK300-III | 2425U262F1 |

| SK200-6 | YN40F00008F1 | SK330 | LC40F00019F1 |

| SK200-6 | YN40F00020FI | SK330-6E | LC40F00009F1 |

| SK200-6 super | YN40F00004F2 | SK330LC V1 | LC40FU0001F1 |

| SK200-8 | YN40F00026F1 | SK330LC-6E | LC40F00009F1 |

| SK200-8 | YN40F00026F2 | SK330-6E | LC40F00012F |

| SK200-10 | Yn40F00042f2 | SK350 | LC40F00018F1 |

| SK-210 | YN40F00033F2 | SK350ME | FG4E9648E-J6 |

| SK210LC | YN40F00019F2 | SK480LC-6 | LS40F00003F1 |

FAQ

1. Q: How do you handle customer complaints regarding slewing bearings?

A: We have a dedicated customer service team. Once we receive a complaint, we will respond within 24 hours, conduct a thorough investigation, and provide a solution within 5 working days.

2. Q: Can your slewing bearings be used in high - speed rotation applications?

A: Yes, some of our slewing bearings are specifically designed for high - speed rotation applications. We use advanced lubrication and structural designs to ensure smooth and stable operation at high speeds.

3. Q: What kind of lubrication methods do your slewing bearings adopt?

A: Our slewing bearings use a combination of grease and oil lubrication methods. Grease lubrication is suitable for general working conditions, providing long - lasting protection, while oil lubrication is applied in high - speed or heavy - load scenarios for better heat dissipation and friction reduction. We also offer customized lubrication solutions based on specific usage requirements.

4. Q: Can your slewing bearings be integrated with monitoring systems?

A: Absolutely. We can equip our slewing bearings with sensors for real - time monitoring of parameters like temperature, vibration, and load. This allows for early detection of potential issues, enabling predictive maintenance and improving overall equipment reliability.

5. Q: How do you ensure environmental friendliness in production?

A: We comply with international environmental standards throughout the production process. Our factory uses energy - efficient equipment, recycles waste materials, and minimizes emissions. Additionally, the materials we select for slewing bearings are environmentally safe and recyclable.

Product Display

Hefei King Slewing Bearing Technology Co., Ltd.

If you have any needs, please feel free to contact me and I will be happy to serve you.