+86-13349293098

+86-13349293098

01

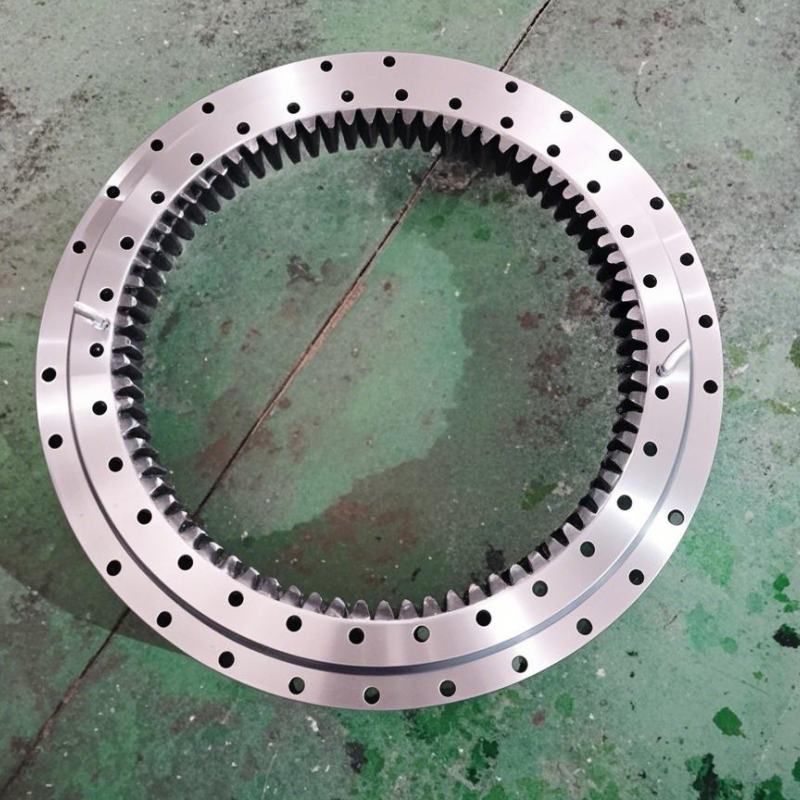

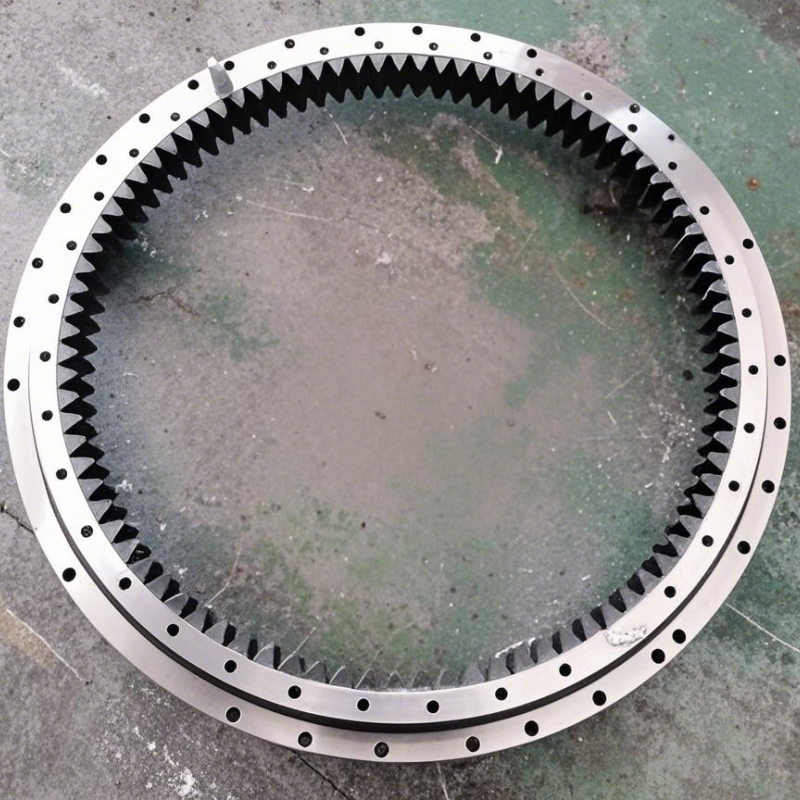

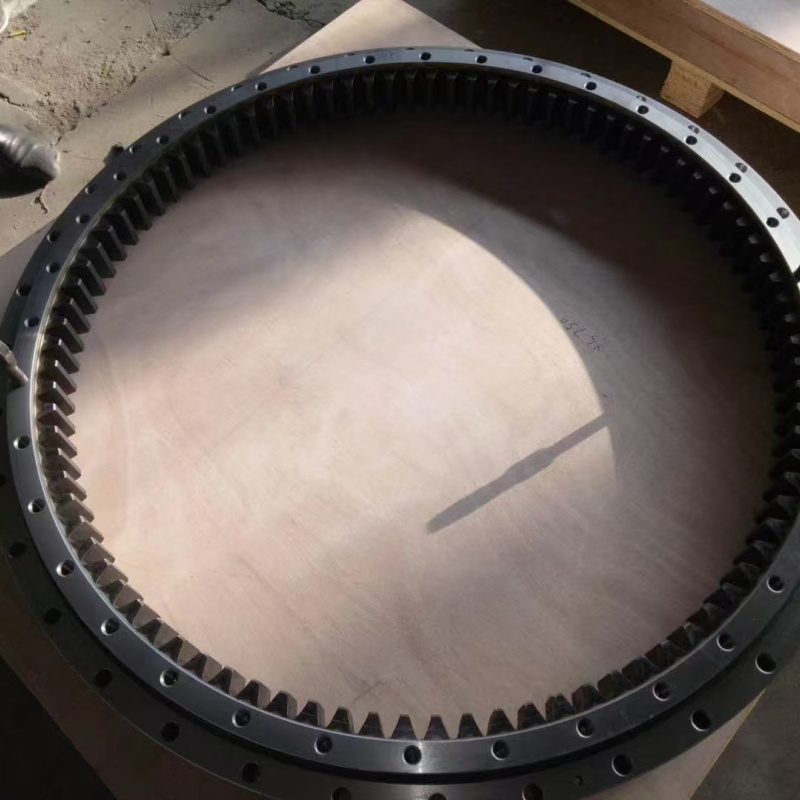

Hitachi Excavator EX100-1 Slewing Bearing 9098995

Why choose us

Excellent weather resistance and corrosion resistance

In response to different harsh working environments, we carry out special surface treatments on the slewing bearings, such as hot-dip galvanizing, special coating and other processes. Whether it is the equipment on offshore platforms that are exposed to the humid marine environment for a long time, or the machinery in industrial environments with high dust levels and strong acid and alkali, our slewing bearings can withstand corrosion and maintain excellent performance.

Excellent Load-bearing Capacity

Our slewing bearings are precisely designed and manufactured. Made of high-strength alloy steel and with an optimized internal structure, they can easily meet the load-bearing requirements of various equipment, ranging from light-duty devices to heavy-duty machinery. Whether it is the frequent lifting operations of construction cranes or the ultra-heavy-duty operation of port loading and unloading equipment, our slewing bearings can provide stable support, ensuring the safe and efficient operation of the equipment.

Product Model List

|

Hitachi |

|||

|

Model |

Part Number |

Model |

Part Number |

|

EX60-2 |

4193433 |

ZX230 |

9154037 |

|

EX60WD -2 |

4193433 |

ZX230 |

9159646 |

|

EX60-5 |

43767553 |

ZX240 |

9196732 |

|

EX100 |

9098995 |

ZX240 |

9245728 |

|

EX100-3 |

9102726 |

EX300-3 |

9112188 |

|

ZX135 |

9184497 |

ZX330LC-5G |

9245698 |

|

EX150-5 |

9146953 |

ZX350-3 |

9245698 |

|

EX200 |

9098993 |

ZX370 |

9166468 |

|

ZX200LC-5G |

9260971 |

ZX370 |

9169894 |

|

ZX200-3 |

9260971 |

KH180-3 |

9099074 |

|

EX200-3 |

9148123 |

HE6010B |

1214DBS110T |

|

ZX200 |

9196732 |

EX400 |

164-2568 |

|

ZX200-5G |

9260971 |

EX400-5 |

9129521 |

|

EX200 |

9102727 |

ZX450 |

9129521 |

|

EX210-5 |

9102727 |

ZX450-3 |

9247287 |

|

ZX210LCK |

9169646 |

ZX450-3 |

9247287 |

|

ZX210W-1 |

9275368 |

ZX470-3 |

9247287 |

FQA

1.Q: Do you offer training services for slewing bearing operation and maintenance?

A: Yes, we provide comprehensive training programs for our customers. These cover proper operation, routine maintenance, and troubleshooting techniques for slewing bearings. Our training can be conducted online or on - site, tailored to the specific needs of your team.

2. Q: What is your production capacity per month?

A: Our monthly production capacity can reach [X] units, which can be flexibly adjusted according to order volumes. With our automated production lines and efficient workforce, we can meet both large - scale and urgent orders.

3. Q: Can you supply slewing bearings with special anti - corrosion coatings?

A: Yes, we offer various anti - corrosion coatings, including zinc plating, epoxy coating, and specialized anti - rust paints. These coatings significantly enhance the lifespan of slewing bearings in corrosive environments, such as marine or chemical industries.

4. Q: How do you manage the supply chain for raw materials of slewing bearings?

A: We maintain long - term partnerships with reliable raw material suppliers who meet our strict quality standards. Through regular audits and performance evaluations, we ensure stable material supply. Additionally, we keep a strategic inventory to prevent shortages and can quickly adapt to fluctuations in demand.

5. Q: Are your slewing bearings suitable for low - temperature environments?

A: Yes, we have developed slewing bearings specifically designed for low - temperature conditions. By using special low - temperature - resistant materials and lubricants, our bearings can maintain excellent performance even in extremely cold climates, ensuring smooth operation without brittleness or freezing issues.

Transportation way

By sea/ air/ rail/ road/ TNT/DHL/UPS/Fedex,ect.

Product Display

Hefei King Slewing Bearing Technology Co., Ltd.

If you have any needs, please feel free to contact me and I will be happy to serve you.