+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

As the 138th Canton Fair 2025 approaches, the spotlight on innovations in Wheel Lift Cylinder technology is set to illuminate significant trends and market data within the industry. Recent market analysis reports predict a robust growth rate of around 6.5% annually in the hydraulic cylinder sector, driven mainly by the increasing demand for advanced lifting solutions in construction and manufacturing. With the integration of IoT and automation, Wheel Lift Cylinders are evolving to meet stringent efficiency and safety standards, as highlighted in a recent industry report by MarketsandMarkets, which outlines that the global market for hydraulic cylinders is expected to reach USD 18 billion by 2027. This fair provides an unparalleled platform for manufacturers and suppliers to showcase cutting-edge technologies and explore potential collaborations that align with these emerging trends. The future of Wheel Lift Cylinder innovation not only reflects the industry's response to market demands but also underscores the commitment to sustainability and enhanced productivity.

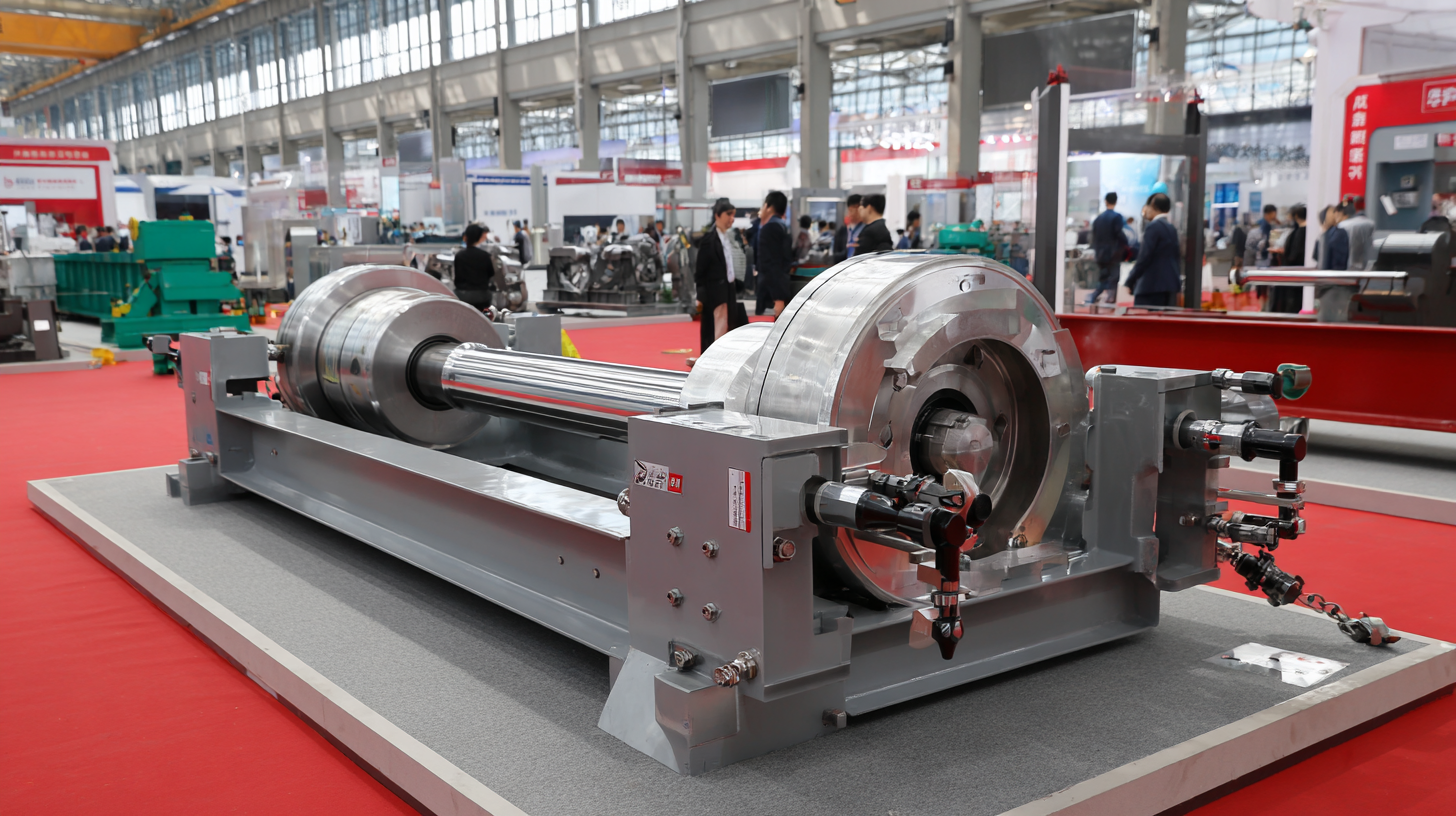

The 138th Canton Fair serves as a platform for showcasing the latest innovations in various industries, and this year, the spotlight is on the innovative designs of wheel lift cylinders. Manufacturers are unveiling cutting-edge technologies aimed at enhancing efficiency and safety in material handling and automotive sectors. These advancements highlight the industry's commitment to sustainability and performance, reflecting broader market trends towards eco-friendly solutions.

Tips for Industry Professionals: When exploring new technologies, consider the importance of sustainability and energy efficiency in your procurement processes. Selecting products that prioritize these factors can not only reduce operational costs but also align your business with global environmental trends.

Additionally, the interactive displays and demonstrations at the fair provide invaluable insights into the practical applications of these innovative designs. Attendees can engage with experts and gain firsthand experience, allowing for informed decision-making when considering upgrades to their existing machinery. Embrace the opportunity to network and exchange ideas on the future of wheel lift cylinder technology.

| Innovation Type | Material Used | Weight (kg) | Load Capacity (tons) | Price Range (USD) | Market Trend |

|---|---|---|---|---|---|

| Hydraulic Cylinder | Steel | 50 | 10 | 200-250 | Increasing Demand |

| Pneumatic Cylinder | Aluminum | 30 | 5 | 150-200 | Stable |

| Electric Cylinder | Composite Material | 40 | 8 | 250-300 | Growing Interest |

| Compact Cylinder | Stainless Steel | 25 | 3 | 100-150 | Niche Market |

The wheel lift cylinder industry is poised for significant advancements in 2025, driven by market trends that favor increased efficiency and automation in hydraulic systems. Innovations showcased at events like the

138th Canton Fair will likely reflect the growing demand for lightweight, durable materials and enhanced performance features. As manufacturers align their products with emerging technologies in electrification and automation, the need for sophisticated

wheel lift cylinders becomes paramount. This aligns with broader industry movements, including a shift towards sustainable practices and the integration of advanced manufacturing techniques.

Furthermore, the hydraulic market is evolving, impacted by factors such as the growth of electric vehicles and the push for improved hydraulic efficiency in machinery. The anticipated rise in global hydraulic systems, predicted to grow steadily by 4% through 2028, suggests a ripe environment for new developments in wheel lift cylinder technology. With players in the market likely focusing on solutions that reduce operational costs while enhancing safety and performance, 2025 promises to be a pivotal year for innovations in this space.

The 138th Canton Fair in 2025

The fair serves as a pivotal platform for industry experts and key players in the wheel lift cylinder market. This segment of the material handling industry is projected to grow significantly, with market reports indicating a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030. Prominent manufacturers are showcasing innovative technologies focused on enhancing performance and durability, meeting the increasingly rigorous demands of various industrial applications.

Leading companies such as Omnipower, Hynaut, and GreenMax are unveiling their latest wheel lift cylinder designs, which feature advancements like improved hydraulic systems and lightweight materials. According to a recent industry insight report, about 75% of industry leaders emphasize sustainability as a core principle driving their R&D efforts.

The fair is not just a platform for product showcases but also fosters collaboration and partnerships among manufacturers, suppliers, and distributors, which could reshape market dynamics in the coming years. The insights gathered from this event will be crucial for participants looking to navigate the evolving landscape of the wheel lift cylinder industry effectively.

At the 138th Canton Fair in 2025, innovations in wheel lift cylinders underscore a significant advancement in efficiency driven by technological progress. Recent reports indicate that the integration of smart sensors and advanced materials in wheel lift cylinders can enhance operational efficiency by up to 30%. This improvement is not only a boon for manufacturers but also aligns with the pressing demand for sustainability in industrial technologies. As the industry shifts towards more intelligent systems, the adoption of these innovations holds the potential to revolutionize logistics and automotive sectors, ensuring higher productivity with lower energy consumption.

At the 138th Canton Fair in 2025, innovations in wheel lift cylinders underscore a significant advancement in efficiency driven by technological progress. Recent reports indicate that the integration of smart sensors and advanced materials in wheel lift cylinders can enhance operational efficiency by up to 30%. This improvement is not only a boon for manufacturers but also aligns with the pressing demand for sustainability in industrial technologies. As the industry shifts towards more intelligent systems, the adoption of these innovations holds the potential to revolutionize logistics and automotive sectors, ensuring higher productivity with lower energy consumption.

Technological advancements, particularly in automation and IoT integration, are pivotal in transforming wheel lift cylinder functionality. A recent study highlights that leveraging real-time data can minimize downtime by 20% in commercial applications, thereby optimizing maintenance schedules and extending equipment lifespan. Furthermore, the push towards electric vehicle technology noted in industry analyses indicates an increasing reliance on efficient hydraulic systems, where wheel lift cylinders play a crucial role. As the market evolves, manufacturers focusing on these technological enhancements are likely to gain a competitive edge, producing not only more efficient machinery but also contributing to a more sustainable manufacturing ecosystem.

The 138th Canton Fair in 2025 showcased significant innovations in wheel lift cylinder manufacturing, with a strong emphasis on sustainability. Manufacturers are increasingly adopting eco-friendly materials and processes to reduce their environmental impact. Cutting-edge technologies such as advanced recycling methods and energy-efficient production techniques are becoming prevalent. This shift not only aids in minimizing waste but also aligns with global efforts towards a circular economy, reflecting consumer demand for environmentally responsible products.

Additionally, the implications of these sustainable practices extend beyond just manufacturing. Companies that embrace sustainability are likely to enhance their brand image and meet the growing expectations of conscious consumers. Market data indicates a rising trend in consumer preference for products that are not only functional but also environmentally friendly. As a result, innovators in the wheel lift cylinder sector are not only revolutionizing their manufacturing processes but also positioning themselves favorably in a competitive market by prioritizing sustainability. This strategic move is expected to yield long-term benefits both environmentally and economically.