+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

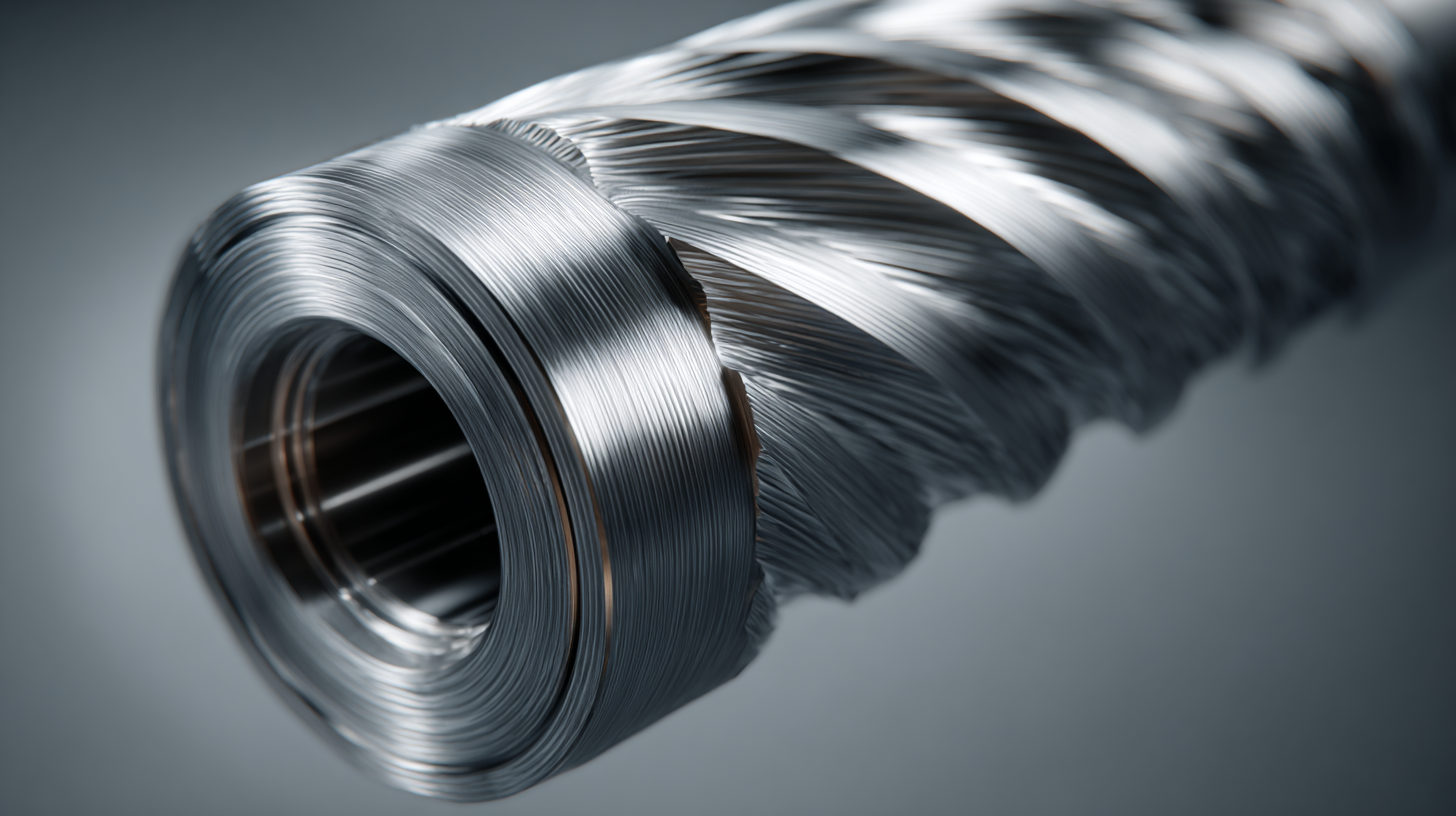

In the realm of modern engineering, the Twist Cylinder has emerged as a pivotal component in various applications, ranging from aerospace to automotive industries. Recent industry reports indicate that the global market for advanced cylinder technologies is anticipated to reach $15 billion by 2025, with a significant shift toward innovative designs like the Twist Cylinder, which enhances torque transmission and efficiency. This engineering marvel leverages the principles of mechanical advantage and strain energy, providing solutions that are not only efficient but also reduce material consumption by 30%. As the push for sustainable practices continues to grow, understanding the mechanics and applications of Twist Cylinders becomes essential for engineers seeking to optimize performance while minimizing environmental impact. Through this exploration, we aim to highlight the critical role of Twist Cylinders in shaping the future of engineering innovation.

Twist cylinders, characterized by their unique geometric configuration, have emerged as pivotal components in various engineering applications. The geometry of a twist cylinder features a helical shape, allowing for the distribution of stress and strain in ways that enhance structural efficiency. According to a report from the ASME (American Society of Mechanical Engineers), the integration of twist designs in load-bearing structures can lead to weight reductions of up to 30% without compromising performance. This has significant implications for industries where material cost and weight are critical factors, such as aerospace and automotive engineering.

In terms of properties, twist cylinders are recognized for their torsional strength and flexibility. Research published in the Journal of Materials Science indicates that these structures exhibit superior capability in absorbing energy during dynamic loading scenarios, making them ideal for applications in shock absorbers and protective gear. Additionally, advancements in materials science have led to the development of composite twist cylinders that combine high strength-to-weight ratios with corrosion resistance, further broadening their applicability across sectors. This evolving landscape showcases the importance of understanding the geometry and mechanical properties of twist cylinders as they pave the way for innovative engineering solutions.

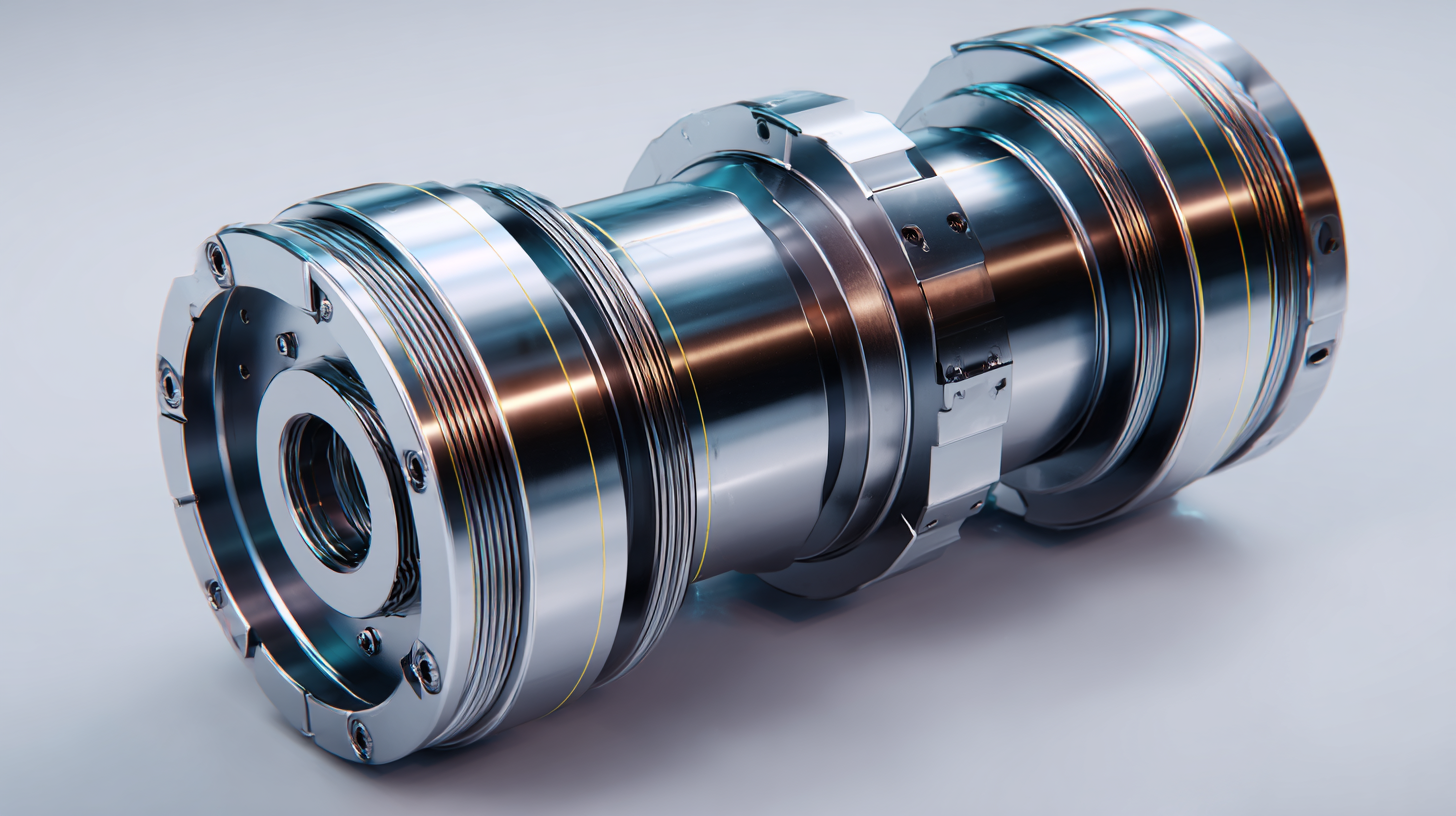

Designing twist cylinders requires a multifaceted approach that blends engineering principles with cutting-edge computational methods. Recent industry reports indicate that the global market for twist-based applications is projected to reach $5 billion by 2025, emphasizing the growing significance of this technology in engineering. Critical considerations in the design process include material selection, geometric optimization, and stress analysis, as these factors directly influence the performance and durability of twist cylinders in their respective applications.

Advanced computational methods, such as finite element analysis (FEA) and computational fluid dynamics (CFD), play an essential role in the design of twist cylinders. These techniques enable engineers to simulate the mechanical behavior and fluid interactions within the cylinders, allowing for optimization in real-time. According to a 2023 survey conducted by the American Society of Mechanical Engineers, 78% of engineers reported that employing FEA significantly reduced prototyping costs and development time, highlighting the efficiency gained through these advanced methodologies. As the demand for innovative engineering solutions continues to rise, the integration of these computational tools in twist cylinder design will be paramount to achieving enhanced performance and sustainability in various applications.

Twist cylinders, characterized by their unique structural form, have found significant applications in both structural engineering and the aerospace industry. In structural engineering, these components are utilized for their ability to efficiently distribute loads while providing exceptional stability. The inherent twisting of these cylinders allows for a lightweight design that does not compromise strength, making them ideal for high-rise buildings and bridges where weight reduction is crucial. Their design optimization leads to enhanced energy absorption, which is particularly beneficial in seismic regions where buildings must withstand dynamic loads.

In the aerospace sector, twist cylinders play a pivotal role in the development of aircraft structures and components. Their ability to endure extreme aerodynamic forces while maintaining structural integrity allows engineers to create more efficient and lighter aircraft designs. Additionally, the versatility of twist cylinders enables their incorporation in various systems, from wing designs to fuselage reinforcements. The innovative use of materials combined with twist geometry provides not only enhanced performance but also improved fuel efficiency, contributing to the ongoing quest for sustainable aviation technologies. The application of twist cylinders thus represents a blend of advanced engineering principles and practical performance benefits across these critical industries.

| Application Area | Feature of Twist Cylinder | Benefits | Example Usage |

|---|---|---|---|

| Structural Engineering | Enhanced Load Distribution | Improves stability and reduces material usage | Twist cylinders in bridges and towers |

| Aerospace Engineering | Weight Efficiency | Enhances fuel efficiency and payload capacity | Twist cylinder designs in aircraft fuselages |

| Automotive Engineering | Vibration Damping | Improves ride quality and vehicle longevity | Suspension systems utilizing twist cylinders |

| Construction | Seismic Resistance | Increases structural resilience in earthquakes | High-rise buildings employing twist cylinder designs |

The manufacturing landscape is rapidly evolving with innovative approaches to fabricating and testing twist cylinders, which play a crucial role in various engineering applications. These cylindrical structures are essential for creating complex systems in automotive, aerospace, and mechanical engineering. Recent advancements in robotics have significantly enhanced the precision and efficiency of manufacturing processes, enabling the production of intricate twist cylinder designs that were previously challenging to achieve.

Tips: When considering the fabrication of twist cylinders, utilizing advanced industrial robots can streamline the process. These robots not only reduce human error but also allow for repetitive tasks to be performed with outstanding accuracy, thus maintaining product quality. Moreover, incorporating real-time testing methods during production can identify imperfections early, ensuring that only the finest components make it to the final assembly stage.

The synergy between robotic automation and modern manufacturing techniques is transforming how twist cylinders are developed and tested. By leveraging innovative technologies, engineers can push the boundaries of design while optimizing production timelines and costs. As industry needs evolve, these advancements will continue to play a pivotal role in shaping the future of manufacturing.

The use of twist cylinders in modern engineering presents unique opportunities and challenges, particularly in the pursuit of advanced materials. As researchers continue to explore the geometric and mechanical properties of twist cylinders, the integration with emerging technologies enhances the capabilities of these structures. A recent review on 4D-printed hygromorphs highlights the potential of materials that can adapt their shape—a characteristic not unlike that of twist cylinders under varying conditions. The ability of these materials to expand and morph in response to environmental stimuli can revolutionize applications in aerospace, robotics, and medical devices.

Despite these advancements, hurdles remain in material performance and manufacturing scalability. Industry reports indicate that while the global market for advanced materials is projected to reach USD 111 billion by 2026, the current limitations in material durability and programmable behavior pose significant development challenges. Moreover, achieving precise control over the transformation behavior of twist cylinders will require significant strides in additive manufacturing techniques. As we look towards the future, the collaboration between materials science and robotics could pave the way for innovative applications that leverage the dynamic capabilities of twist cylinders and related technologies.

This chart illustrates the performance index of twist cylinders across various applications, highlighting their efficiency in advanced materials usage. The data showcases different applications and provides insight into the effectiveness of twist cylinders in modern engineering contexts.