+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

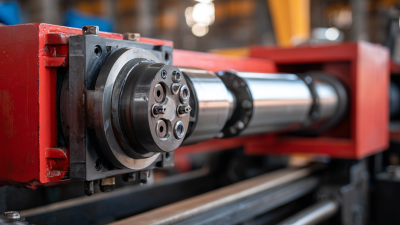

The design of Twist Cylinders has become a pivotal focus in modern engineering, particularly in the fields of automotive and aerospace applications. According to the Global Market Insights report, the demand for advanced cylinder designs is expected to grow at a CAGR of over 5% between 2023 and 2030, driven by the necessity for improved efficiency and performance. This growth is largely attributed to advancements in materials and manufacturing techniques that allow for more complex geometries and enhanced mechanical properties. Understanding the mechanics involved in Twist Cylinder design not only helps in optimizing performance but also facilitates innovations that can lead to significant reductions in weight and materials usage—critical factors in achieving sustainability goals. The implementation of precise engineering principles in Twist Cylinder configurations can result in substantial improvements in functionality and reliability across various engineering disciplines.

Twist cylinder design plays a pivotal role in modern engineering, particularly in enhancing the efficiency of various systems such as engines, fluid dynamics, and even in structural applications. At its core, the key principles of twist cylinder design revolve around the geometric and material optimization to achieve desired performance outcomes. According to a report by the International Journal of Advanced Engineering Research and Science, the optimization of twist angles can lead to a 15-20% increase in fluid flow efficiency, showcasing the profound impact of precise design parameters.

Moreover, the integration of advanced materials in twist cylinder construction is revolutionizing engineering practices. High-strength, lightweight composites enable engineers to design twist cylinders that not only withstand higher pressures but also reduce overall weight, thus improving energy efficiency. A study published in the Materials Science and Engineering journal highlighted that using carbon fiber-reinforced plastics (CFRPs) in twist cylinder designs can reduce weight by up to 40% compared to traditional metal options, significantly influencing performance and sustainability in applications from aerospace to automotive engineering. These innovative approaches underline the critical importance of twisting geometry and material choices in modern engineering solutions.

| Design Feature | Description | Importance | Common Materials |

|---|---|---|---|

| Twist Angle | The angle at which the cylinder is twisted along its axis. | Affects performance, torque, and efficiency. | Aluminum, Steel, Composite Materials |

| Diameter | The outer diameter of the cylinder. | Determines strength and torque transfer capability. | Steel, Titanium, Carbon Fiber |

| Length | The total axial length of the twist cylinder. | Affects leverage and torque application. | Aluminum, Steel, Plastic |

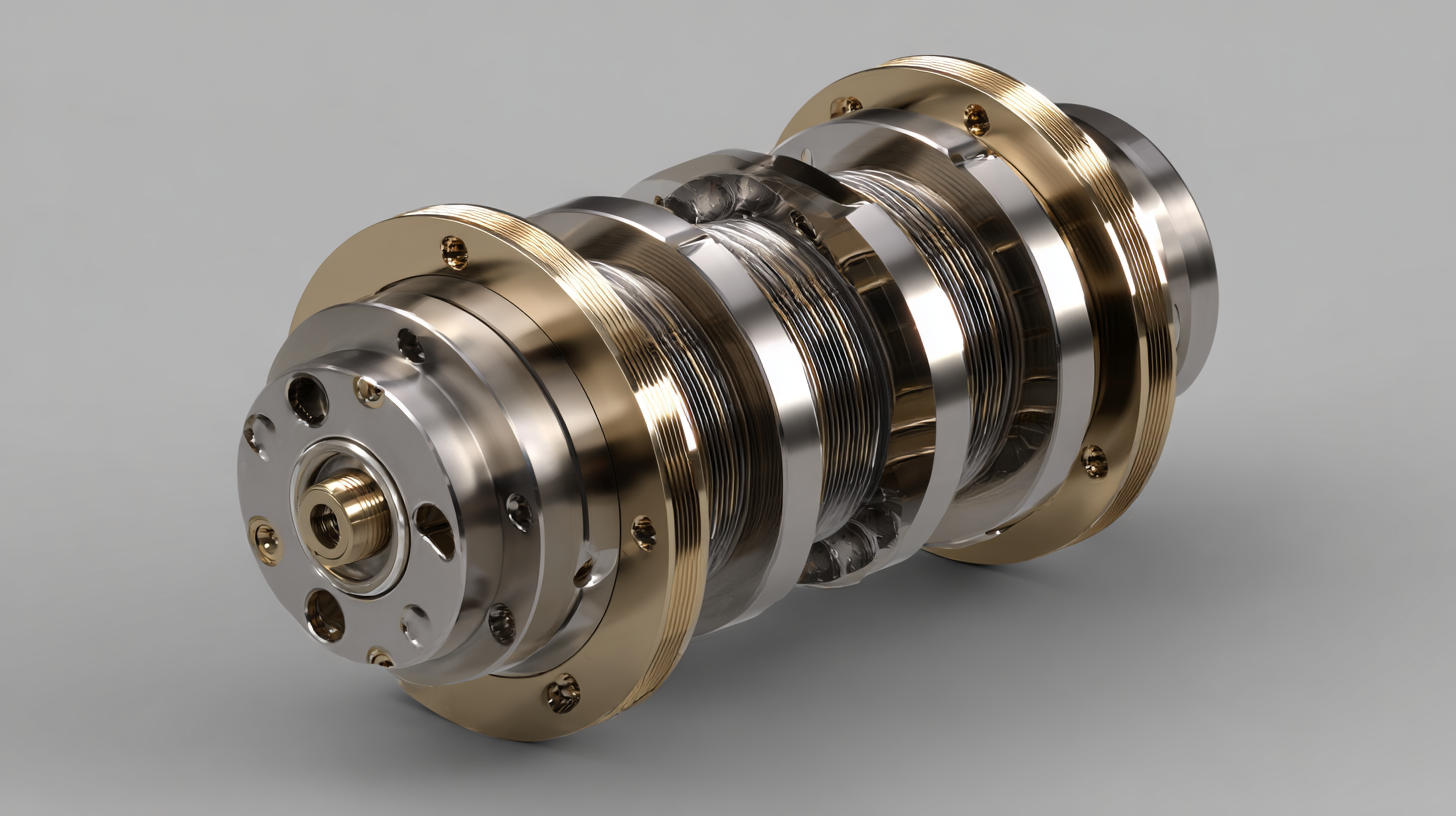

| Twist Shaft Design | The structural design of the shaft within the cylinder. | Maximizes efficiency and effectiveness in force application. | Carbon Steel, Alloy Steel, Composites |

| Surface Treatment | Processes applied to enhance durability and reduce friction. | Improves lifespan and performance under stress. | Anodizing, Hard Coating, Plating |

In modern engineering, the fabrication of twist cylinders typically involves the integration of advanced materials that can enhance performance and durability. One of the essential materials used is high-strength aluminum alloys. These alloys are favored for their lightweight properties, which contribute to improved efficiency in applications such as aerospace and automotive engineering. Their excellent strength-to-weight ratio ensures that the twist cylinders can withstand significant stress while minimizing overall mass.

Another crucial material is carbon fiber reinforced polymer (CFRP). This composite material is particularly advantageous due to its exceptional stiffness and resistance to fatigue. The use of CFRP allows for the creation of twist cylinders that not only perform well under extreme conditions but also exhibit a high degree of customization in design. Furthermore, the corrosion resistance of CFRP makes it ideal for applications in harsh environments, ensuring longevity and reliability.

Finally, stainless steel plays a pivotal role in certain applications of twist cylinder design. Its inherent strength, coupled with excellent corrosion resistance, makes stainless steel an ideal choice for environments where durability is paramount. This versatility allows engineers to select the appropriate material based on specific operational requirements, further enhancing the efficiency and effectiveness of twist cylinder designs in modern engineering.

The twist angle in a twist cylinder design significantly influences mechanical performance, affecting factors such as strength, stiffness, and energy absorption. A well-calibrated twist angle can enhance the load distribution along the length of the cylinder, which is crucial for applications ranging from aerospace engineering to automotive components. By optimizing the twist angle, engineers can achieve a balance between flexibility and rigidity, allowing for improved performance under varying operational conditions.

Additionally, the twist angle can alter the stress distribution within the material. An increase in twist can lead to asymmetrical load distributions, which may cause localized stress concentrations. Understanding these dynamics enables engineers to better predict failure modes and implement designs that mitigate potential issues. Through careful analysis and simulation, it becomes possible to identify the optimal twist angle that maximizes performance while minimizing the risk of structural failure, ultimately leading to more reliable and efficient mechanical systems.

The functionality of twist cylinders, integral components in various engineering applications, relies heavily on rigorous testing methods to ensure their operational integrity and performance. According to a report by the American Society of Mechanical Engineers (ASME), nearly 30% of mechanical failures in industrial applications stem from inadequate testing protocols during the design phase. This statistic underscores the necessity of comprehensive testing methods, which include pressure testing, fatigue testing, and thermal analysis, all designed to simulate real-world operational conditions.

One prevalent approach in validating the functionality of twist cylinders is finite element analysis (FEA), which allows engineers to predict how these components behave under various loads. A study published in the Journal of Applied Mechanics found that implementing FEA can lead to a 40% reduction in prototype iterations, significantly saving both time and resources. Furthermore, on-site performance testing is crucial; a survey by the International Society of Automation revealed that up to 25% of twist cylinders underperform due to unanticipated environmental factors. This combination of advanced simulation and practical testing ensures that twist cylinder designs are not only innovative but also reliable in their application across modern engineering fields.

The evolution of twist cylinder design is increasingly influenced by innovative techniques drawn from the realm of origami. As engineers seek to create adaptable and efficient structures, incorporating origami principles into twist cylinder designs showcases the potential for compactness and versatility. This approach allows for the fabrication of components that can change shape, providing functionality in varied spaces and applications, significantly impacting fields such as aerospace and robotics.

Recent advancements highlight the emergence of new design methods and tools that facilitate the integration of origami concepts into engineering practices. These tools not only streamline the design process but also enhance the ability to prototype and test twist cylinder configurations rapidly. As industries experiment with these innovative strategies, the future of twist cylinder design promises a wave of creativity, leading to more sustainable and efficient engineering solutions. The insights gained from recent studies underscore the importance of collaboration between traditional engineering principles and modern design techniques, opening pathways for new applications in various sectors.