+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

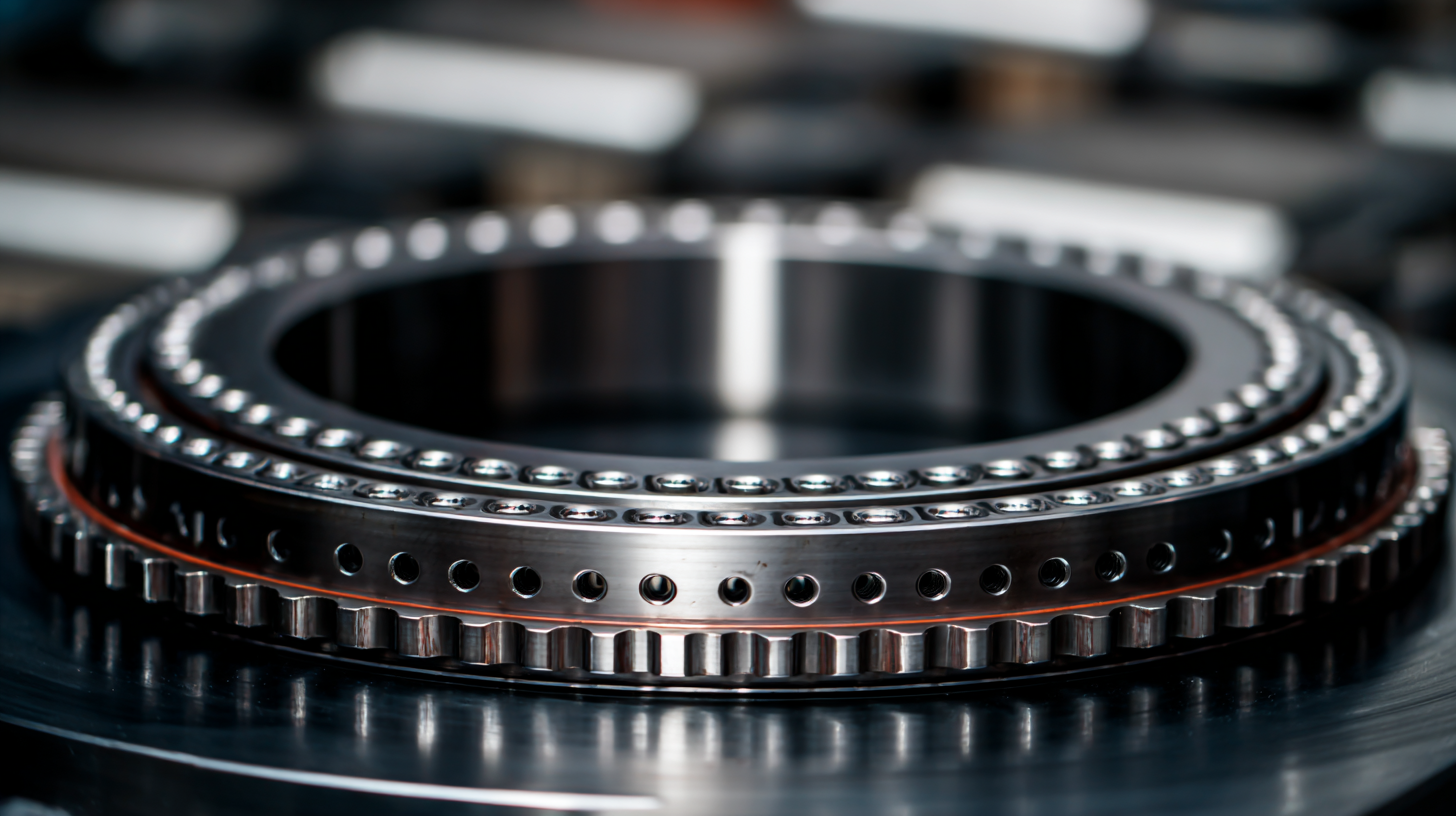

In the realm of modern construction equipment, Slewing Circle Bearings play a pivotal role in ensuring operational efficiency and stability. These sophisticated components facilitate the smooth rotational movement of heavy machinery, enabling tasks such as excavation, lifting, and material handling with precision. Understanding the types of Slewing Circle Bearings available, along with their unique performance metrics, is essential for engineers and operators aiming to optimize equipment performance and longevity. This introduction delves into the various configurations and specifications of Slewing Circle Bearings, highlighting how factors such as load capacity, speed, and environmental conditions influence their effectiveness. By exploring these aspects, we aim to shed light on the crucial impact that Slewing Circle Bearings have on enhancing the reliability and productivity of contemporary construction operations.

Slewing circle bearings play a crucial role in enhancing the mobility and operational efficiency of modern construction machinery. These bearings are essential components in heavy equipment, such as cranes and excavators, where they allow for controlled rotation and movement. Given that the global bearings market is projected to grow significantly, reaching USD 97.10 billion by 2030, it underscores the increasing demand for solutions that improve machinery performance and ergonomics within the construction industry.

The ability of slewing circle bearings to provide smooth rotational motion contributes to the efficiency of operations, particularly in complex work environments. For instance, they enable cranes to lift and reposition materials swiftly and accurately, significantly reducing downtime and enhancing productivity. With the integration of modern technologies like automation and electrification, as highlighted in recent industry launches, the role of slewing bearings is set to evolve further, leading to improved machinery capabilities and performance metrics that meet the rigorous demands of today's construction projects.

Slewing circle bearings play a crucial role in the functionality of modern construction equipment, notably in rotating machinery such as cranes, excavators, and aerial work platforms. Evaluating the efficiency of these bearings involves analyzing several key performance metrics. One primary metric is the load capacity, which must be adequate to support both static loads and dynamic forces during operation. This ensures the safety and reliability of equipment under various working conditions.

Another vital performance metric is the rotational speed, which reflects how quickly the machinery can operate without compromising stability or causing excessive wear on the bearing. The friction coefficient also serves as a critical indicator; lower friction values contribute to enhanced efficiency and reduced energy consumption, ultimately translating to lower operational costs. Additionally, the lifespan of slewing circle bearings significantly impacts overall performance; longevity can be assessed through regular maintenance checks and monitoring wear patterns, ensuring timely replacements and minimizing downtime on job sites.

| Metric | Description | Typical Value | Unit |

|---|---|---|---|

| Load Capacity | Maximum load a bearing can support | 50,000 | N (Newtons) |

| Rotational Speed | Maximum speed at which the bearing can rotate | 3.0 | RPM (Revolutions Per Minute) |

| Service Life | Expected lifespan of the bearing under normal conditions | 10,000 | Hours |

| Friction Coefficient | Ratio of frictional force to the normal force | 0.005 | Unitless |

| Temperature Resistance | Maximum temperature the bearing can withstand | 120 | °C (Celsius) |

Slewing circle bearings are crucial components in modern construction equipment, enabling smooth rotation and enhancing operational efficiency. Understanding the wear patterns of these bearings is essential for maintaining their functionality and prolonging the service life of machinery. Typically, wear can manifest through surface pitting, spalling, or excessive play, which are indicative of inadequate lubrication, misalignment, or overload conditions. Regular monitoring of these indicators can help in identifying early signs of wear, allowing for timely interventions to prevent more severe damage.

Maintenance needs for slewing circle bearings include not only lubrication but also periodic inspections to assess their condition. An effective maintenance regime involves checking for signs of wear, ensuring proper alignment, and verifying that the lubrication system is functioning correctly. Implementing predictive maintenance strategies, such as vibration analysis or temperature monitoring, can also provide invaluable insights into bearing health. By addressing wear patterns proactively, construction equipment operators can enhance the reliability and performance of their machines, ultimately leading to greater efficiency on construction sites.

Slewing circle bearings play a critical role in the functionality and efficiency of various modern construction equipment, providing the necessary support for rotational movement and load distribution. Their application spans across different machinery such as excavators, cranes, and drill rigs, each requiring specific performance metrics to ensure optimal operation. In excavators, for instance, high-load capacity and precision are essential for effective digging and material handling, while cranes necessitate extended reach and stability under dynamic loads.

Comparative analysis of slewing circle bearings across different construction applications reveals variations in design and material selection tailored to meet specific operational demands. For example, heavy-duty cranes often utilize bearings made from high-strength steel with enhanced corrosion resistance to withstand harsh environmental conditions, ensuring longevity and reduced maintenance costs. Conversely, lighter equipment may opt for hybrid materials to reduce weight without compromising durability. Through performance metrics such as load capacity, rotational speed, and lifespan, it becomes evident how these bearings are optimized for each application, ultimately influencing the overall efficiency and reliability of construction operations.

Slewing circle bearings play a pivotal role in enhancing the efficiency and functionality of modern construction equipment. In response to the escalating demands from the marine industry and heavy machinery sectors, innovations in slewing bearing technology have emerged as a key driver for improving performance metrics. These advancements not only cater to the increasing load capacities required by massive offshore cranes but also focus on reducing maintenance needs and prolonging service life, which is vital for today’s rigorous operational environments.

The slewing bearings market is projected to reach $4 billion by 2020, highlighting the critical impact of technological innovations. Manufacturers are now investing in cutting-edge materials and design methodologies to develop slewing bearings that offer superior durability and precision. Features such as enhanced sealing and lubrication systems are being incorporated to ensure reliability and efficiency in challenging conditions. As construction equipment becomes more sophisticated, the role of slewing circle bearings will continue to evolve, leading to significant improvements in the effectiveness of operations across various industries.