+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

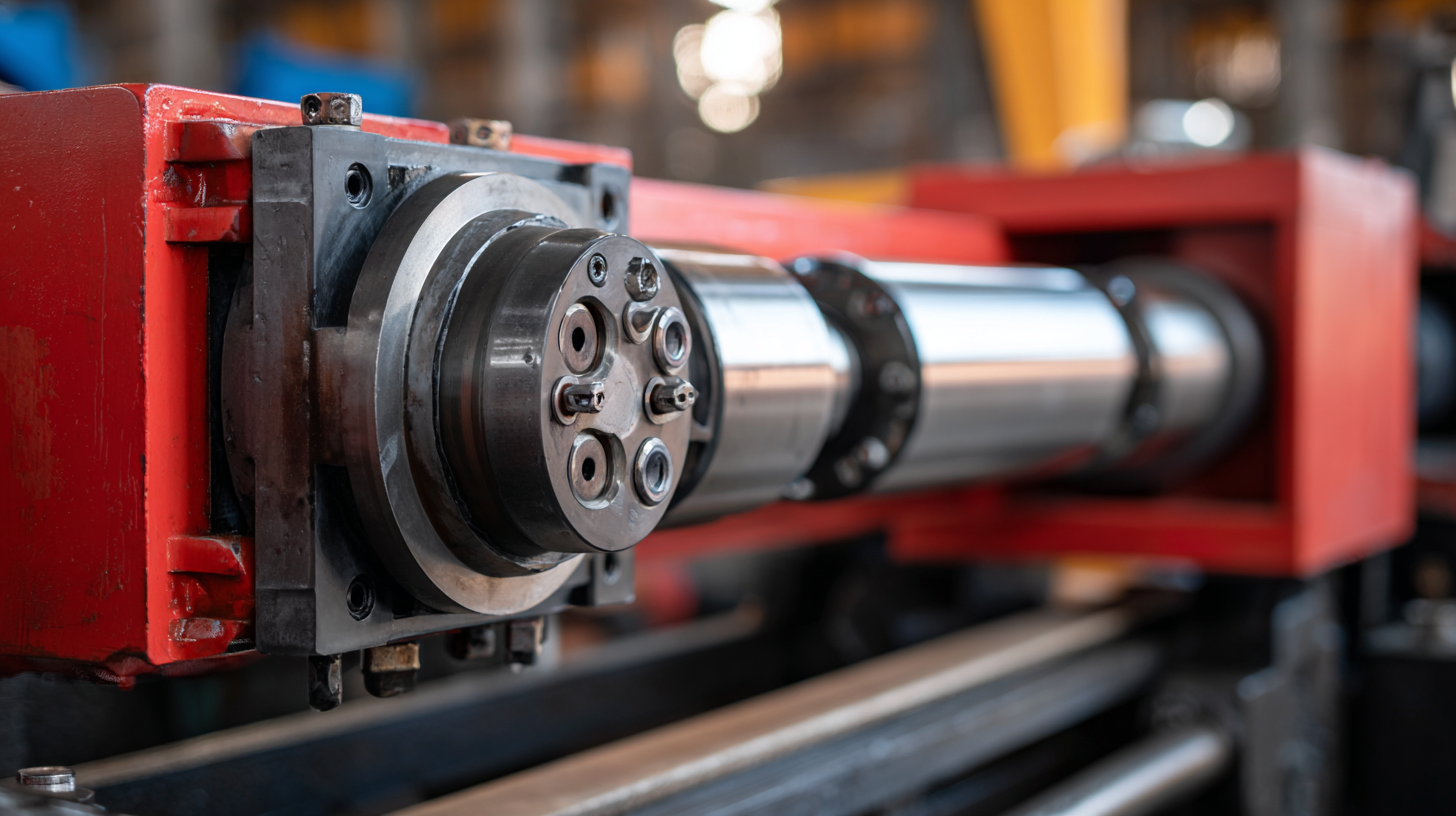

Selecting the right bucket cylinder is crucial for achieving optimal hydraulic performance in various applications, from construction to agriculture. A bucket cylinder is an essential component that directly influences the efficiency and effectiveness of hydraulic systems, enabling precise control and power in machinery. With a wide range of bucket cylinders available, understanding the specific requirements of your machinery and the tasks at hand is pivotal. Factors such as cylinder size, stroke length, mounting style, and pressure ratings play significant roles in determining the best fit for your needs.

This guide aims to provide you with a comprehensive overview of the essential considerations and practical tips for selecting the right bucket cylinder, ensuring your hydraulic systems operate effectively and enhance overall productivity. Whether you are a seasoned professional or a newcomer to hydraulic applications, grasping these principles will empower you to make informed decisions that maximize performance and longevity.

When selecting the right bucket cylinder for optimal hydraulic performance, it's essential to understand the various types present in hydraulic systems. Bucket cylinders are crucial for controlling the movement and lifting capabilities of equipment such as excavators and loaders. The design and functionality of these cylinders can vary significantly, impacting their efficiency and effectiveness in different applications. For instance, load-sensing hydraulic systems allow for better adaptation to varying load conditions, improving overall performance.

When selecting the right bucket cylinder for optimal hydraulic performance, it's essential to understand the various types present in hydraulic systems. Bucket cylinders are crucial for controlling the movement and lifting capabilities of equipment such as excavators and loaders. The design and functionality of these cylinders can vary significantly, impacting their efficiency and effectiveness in different applications. For instance, load-sensing hydraulic systems allow for better adaptation to varying load conditions, improving overall performance.

Recent advancements in hydraulic systems highlight the importance of choosing the appropriate bucket cylinder. For example, innovations aimed at enhancing the performance of aerial lift devices have shown how upgraded hydraulic components can lead to significant operational improvements. The integration of sophisticated hydraulic models in excavators provides insight into how performance can be maximized through careful cylinder selection and system modeling. Therefore, understanding the characteristics and benefits of each bucket cylinder type is vital for achieving the best performance in hydraulic applications across industries.

When selecting a bucket cylinder for optimal hydraulic performance, several key factors must be considered to ensure maximum efficiency and reliability. First, you need to assess the required force and load capacity based on the specific application. This involves evaluating the weight of the materials being handled and the forces exerted during operation. The cylinder's bore size and stroke length also play critical roles, as they directly affect the cylinder's ability to extend and retract smoothly under varying load conditions.

Additionally, the material and construction of the cylinder should not be overlooked. High-quality materials can significantly reduce wear and tear, prolonging the cylinder's lifespan and improving hydraulic efficiency. Sealing systems must also be carefully chosen to prevent leaks and maintain pressure within the cylinder. Finally, consider compatibility with existing hydraulic systems, including oil type and pressure ratings, to ensure seamless integration and optimal performance. Each of these factors contributes to the effective operation of hydraulic equipment and should be meticulously evaluated when making your selection.

Selecting the right bucket cylinder for hydraulic applications significantly hinges on accurately assessing load and pressure requirements. Understanding the weight of the load that the cylinder will lift is crucial; this includes static loads as well as dynamic forces that may occur during operation. You should consider maximum and minimum load values, as this will inform not only the size of the cylinder but also its material and design features to withstand the operational stress.

Additionally, evaluating the pressure requirements is essential for optimal hydraulic performance. Every hydraulic system operates within a specified pressure range, and using a cylinder that aligns with these specifications ensures both efficiency and longevity. Factors such as the hydraulic fluid type, temperature, and system backpressure must also be considered. By matching the operating pressure to the cylinder’s ratings, you can avoid potential failures and enhance the reliability of the overall system.

Proper assessment of these parameters will not only maximize performance but also reduce maintenance costs in the long run.

When selecting the right bucket cylinder for optimal hydraulic performance, evaluating compatibility with existing hydraulic systems and components is crucial. According to the International Fluid Power Society, approximately 70% of hydraulic system failures can be traced back to incompatibility issues. This underscores the importance of ensuring that new components not only meet performance specifications but also integrate seamlessly with existing machinery.

When considering compatibility, it is essential to assess factors such as pressure ratings, fluid type, and mounting configurations. For example, a report from the National Fluid Power Association highlights that using a bucket cylinder with a lower pressure rating than the existing system can lead to premature failure, often resulting in costly downtime. Additionally, the materials used in the cylinder must be compatible with the hydraulic fluid to prevent corrosion or material degradation, which can significantly affect overall system efficiency. Selecting the right cylinder entails thorough evaluations of these aspects to ensure long-term operational reliability.

One of the most common mistakes in selecting a bucket cylinder for hydraulic systems is failing to consider the specific application and operational requirements. Each application may have unique demands regarding load capacity, speed, and stroke length. Neglecting to evaluate these parameters can lead to choosing a cylinder that is either over-engineered, resulting in unnecessary costs, or under-engineered, which may lead to cylinder failure or reduced efficiency. Therefore, it is imperative to assess the working conditions and expected performance thoroughly before making a selection.

Another mistake often encountered is disregarding the importance of compatibility with existing hydraulic systems. Many engineers make the error of focusing solely on the cylinder's specifications without considering how it will integrate with pumps, valves, and hoses already in use. This oversight can lead to poor performance or even damage to the hydraulic system. It's essential to ensure that all components work harmoniously to achieve optimal hydraulic performance, highlighting the need for a comprehensive approach when selecting a bucket cylinder.