+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

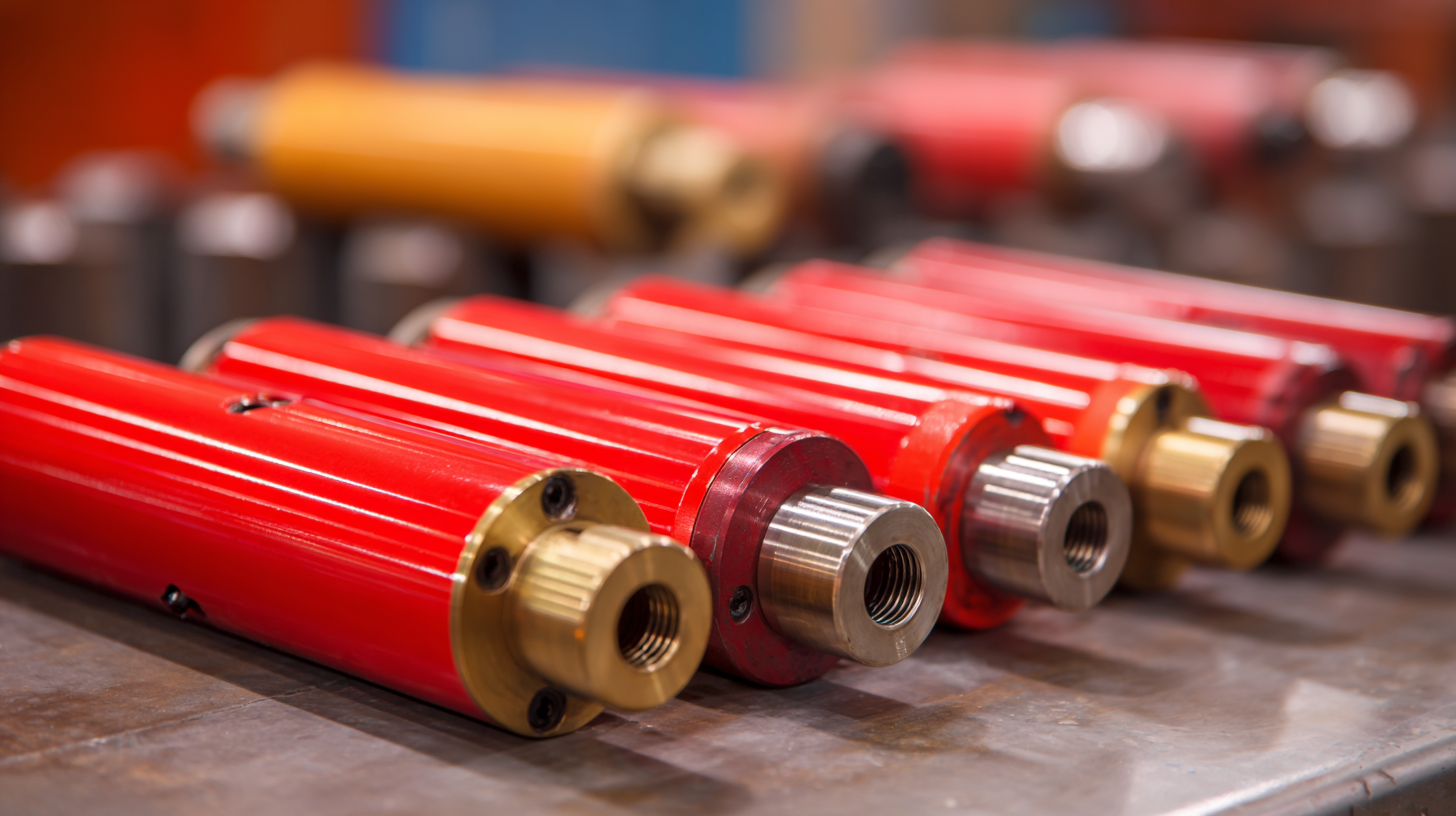

In the world of industrial applications, the significance of precision and reliability cannot be overstated, especially when it comes to hydraulic and pneumatic systems. Among the leading solutions in this field are Red Lion Cylinders, renowned for their robustness and innovative design. According to industry expert John Smith, a senior engineer at Hydraulics Today, "Red Lion Cylinders exemplify the perfect balance of strength and efficiency, making them indispensable in various applications across multiple industries."

These cylinders are engineered to meet the demanding needs of industries such as manufacturing, automotive, and construction, where performance and safety are critical. Featuring advanced materials and technology, Red Lion Cylinders offer exceptional durability while maintaining lightweight properties that enhance operational efficiency. Smith further emphasizes, "With their superior engineering, Red Lion Cylinders not only reduce downtime but also increase productivity, bridging the gap between reliability and innovation in fluid power systems."

As we delve deeper into the features and applications of Red Lion Cylinders, we will uncover how this cutting-edge technology is transforming industrial processes, enabling businesses to achieve unparalleled performance and safety in their operations.

Red Lion cylinders are specialized pneumatic actuators that play a crucial role in various industrial applications. Known for their robust construction and reliability, these cylinders are fundamental in automating processes across sectors such as manufacturing, packaging, and automotive. According to a report by Research and Markets, the global pneumatic cylinder market is projected to grow to $6.5 billion by 2026, highlighting the increasing dependence on efficient automated solutions in industry.

These cylinders are designed to convert compressed air into mechanical energy, enabling precise control over motion and force. With features such as adjustable stroke length and high load capacities, Red Lion cylinders cater to diverse operational needs. A technical report from TechNavio indicates that the demand for custom automation solutions is driving innovation in cylinder design, enhancing performance, and energy efficiency. As industries seek to optimize productivity, the versatility of Red Lion cylinders makes them an essential component in modern automation systems, contributing to improved production workflows and reduced operational costs.

| Feature | Description | Application |

|---|---|---|

| High Strength Material | Constructed from high-grade steel for enhanced durability. | Used in heavy-duty industrial applications. |

| Pressure Resistance | Capable of withstanding high pressure levels. | Ideal for hydraulic systems and pneumatic applications. |

| Lightweight Design | Engineered to be lightweight without compromising strength. | Facilitates easier handling and installation. |

| Corrosion Resistance | Protected with corrosion-resistant coatings. | Suitable for use in harsh environments. |

| Versatility | Compatible with various fluids and gases. | Perfect for diverse industrial setups. |

Red Lion Cylinders have carved out a niche in the industrial market due to their innovative design and robust features. One of the standout characteristics of these cylinders is their superior pressure rating, which often exceeds 10,000 psi. According to a report by the International Association of Pressure Vessel Inspectors, equipment that withstands such high pressure tends to enhance safety and efficiency in various applications, especially in oil and gas industries. Coupled with their lightweight construction, Red Lion Cylinders offer a unique mix of durability and portability, making them ideal for both stationary and mobile usage.

Another key feature that elevates Red Lion Cylinders above their competitors is their corrosion-resistant material. A study from the Materials Science and Engineering journal highlights that corrosion-resistant components can prolong equipment life by up to 30%. This feature is particularly beneficial in harsh environments where traditional materials may fail, thereby impacting operational workflow. Additionally, the seamless design of these cylinders minimizes the risk of leaks, which can be critical in maintaining system integrity and reducing costly downtime in industrial processes. Such advancements not only enhance the reliability of Red Lion Cylinders but also contribute to a more sustainable operational model within the industry.

When selecting the right Red Lion cylinder, it is essential to consider several key features that cater to specific applications. Red Lion cylinders are known for their durability and reliability, making them suitable for heavy-duty tasks in various industries. The materials used in their construction, such as high-strength steel, ensure that these cylinders can withstand significant pressure and harsh environments, which is crucial for long-term performance.

In addition to material selection, understanding the different types and specifications of Red Lion cylinders is vital for making an informed choice. For example, users should consider the intended application and the necessary pressure rating, as these factors directly impact the cylinder's efficiency and effectiveness. Whether you're looking for a cylinder for a specific mechanical task or for a more versatile application, evaluating the dimensions and compatibility with existing systems is crucial for optimal performance.

Red Lion Cylinders have established themselves as versatile components in various industrial applications due to their robust design and reliability. In sectors such as manufacturing, automotive, and construction, these cylinders play a crucial role in enabling efficient operation. According to a report by the Market Research Future, the global pneumatic cylinder market is projected to grow at a CAGR of 5.1% from 2021 to 2027. This growth indicates a rising demand for efficient and durable cylinder solutions, with Red Lion Cylinders at the forefront due to their innovative features.

In the automotive industry, Red Lion Cylinders are frequently utilized for automation in assembly lines, where precise movement and positioning are essential. The cylinders contribute to improved productivity by streamlining processes and reducing downtime. Additionally, in the construction sector, they are employed for lifting and hoisting applications, supporting heavy loads with safety and stability. The Industrial Internet of Things (IIoT) is also influencing the use of these cylinders as companies seek smarter, data-driven solutions to enhance their operational efficiency and reduce maintenance costs. As industries continue to embrace automation, the adaptability of Red Lion Cylinders positions them as a preferred choice for various applications.

This chart illustrates the common applications of Red Lion Cylinders across various industries, highlighting the number of applications in Manufacturing, Construction, Automotive, Aerospace, and Oil & Gas sectors.

Red Lion Cylinders are highly regarded in various industrial applications due to their robust design and innovative features. To ensure their longevity and optimal performance, routine maintenance is essential. According to industry reports, lack of proper maintenance can lead to decreased efficiency and operational failures, which can ultimately increase costs by up to 30%. Regularly inspecting seals, checking pressure gauges, and ensuring proper lubrication can prevent these issues.

Red Lion Cylinders are highly regarded in various industrial applications due to their robust design and innovative features. To ensure their longevity and optimal performance, routine maintenance is essential. According to industry reports, lack of proper maintenance can lead to decreased efficiency and operational failures, which can ultimately increase costs by up to 30%. Regularly inspecting seals, checking pressure gauges, and ensuring proper lubrication can prevent these issues.

Moreover, keeping the cylinders at appropriate temperatures is crucial. Research indicates that operating conditions outside the recommended temperature range can shorten the lifespan of pneumatic cylinders significantly. For Red Lion Cylinders, it is advisable to maintain an environment where temperature fluctuations are minimized. Additionally, implement a routine schedule for cleaning and checking for wear and tear, as this can help identify potential problems before they escalate. Regular maintenance not only enhances the reliability of the cylinders but also optimizes their performance, allowing industries to maximize productivity and minimize downtime significantly.