+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

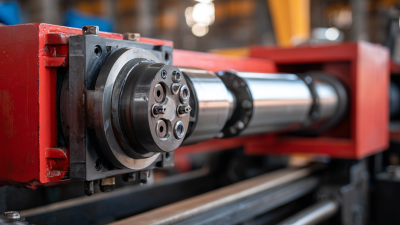

In the ever-evolving landscape of industrial applications, the Bucket Cylinder stands out as a pivotal innovation, enabling enhanced efficiency and versatility across various sectors. According to a report by MarketsandMarkets, the global hydraulic cylinder market is anticipated to reach $9.1 billion by 2027, with a growing emphasis on automation and advanced machinery driving this growth. The Bucket Cylinder, characterized by its unique design and multifunctional capabilities, plays a crucial role in sectors ranging from construction and agriculture to waste management and mining. Its ability to seamlessly perform operations such as lifting, tilting, and transporting materials positions it as a game-changer for industries seeking to streamline workflows while reducing operational costs. As the demand for more efficient and effective equipment continues to rise, exploring innovative uses of the Bucket Cylinder is essential for maximizing productivity and staying competitive in the market.

The innovative uses of bucket cylinders in automation and robotics play a crucial role in enhancing operational efficiency across various industrial sectors. These cylinders, designed for robust performance and versatility, can be integrated into robotic arms and automation systems, offering precise control and smooth operation. For instance, in assembly lines, bucket cylinders enable the effective handling of heavy components, allowing robots to execute tasks with increased speed and precision. This capability not only improves productivity but also reduces the likelihood of human error, ensuring consistent quality in manufacturing processes.

Furthermore, bucket cylinders are instrumental in automating material handling and logistics operations. Their ability to adapt to different load requirements makes them an ideal choice for industries that rely on frequent changes in production demands. By equipping autonomous vehicles with bucket cylinders, companies can streamline their supply chain processes, minimizing downtime and maximizing throughput. In addition, the integration of smart technology with bucket cylinders enables real-time monitoring and adjustments, resulting in optimized performance that contributes significantly to the overall effectiveness of automation systems in today’s fast-paced industrial landscape.

The bucket cylinder has emerged as an innovative component in waste management systems, particularly when integrated with real-time data analytics. According to a report by the Environmental Protection Agency (EPA), effective waste management can reduce landfill waste by up to 30% when technology is properly employed. The bucket cylinder, equipped with sensors and IoT capabilities, can optimize the collection schedules and routes based on actual fill levels, rather than relying on traditional time-based collection. This not only minimizes operational costs but also significantly enhances eco-friendliness by reducing fuel consumption and emissions.

Furthermore, the incorporation of real-time data analytics allows waste managers to gain insights into waste generation patterns and material types, leading to improved recycling rates. A recent study published by the Waste Management Association indicates that cities utilizing data-driven waste management systems have seen a 50% increase in recycling efficiency. The bucket cylinder acts as a critical data collection point, ensuring that municipalities can adapt to changing waste streams promptly, ultimately supporting sustainable practices and contributing to a circular economy.

Precision farming is transforming agriculture by leveraging advanced technologies, and one of the key innovations making waves is the bucket cylinder. This hydraulic component plays a crucial role in various agricultural machinery, enabling farmers to achieve more efficient and effective operations. By integrating bucket cylinder technologies into tractors and harvesters, farmers can enhance their ability to regulate the application of water, nutrients, and pesticides, ensuring that resources are used optimally while minimizing waste.

Tips: When considering bucket cylinder integration, assess the specific needs of your farming operation. Selecting the right size and strength of the bucket cylinder is vital for achieving the desired performance. Additionally, regular maintenance checks on hydraulic systems will ensure longevity and dependability in the field.

Moreover, the versatility of bucket cylinder applications extends beyond traditional farming tactics. In the age of automation, these cylinders are essential in precision planting and controlled seed placement, particularly suited for both small and large-scale operations. By harnessing the power of data analytics alongside bucket cylinder technology, farmers can precisely monitor soil conditions and crop health, leading to informed decisions that bolster yield.

Tips: Implementing sensors to gather critical information about soil moisture and nutrient levels can help you fine-tune the use of bucket cylinders, allowing for targeted interventions that improve crop productivity.

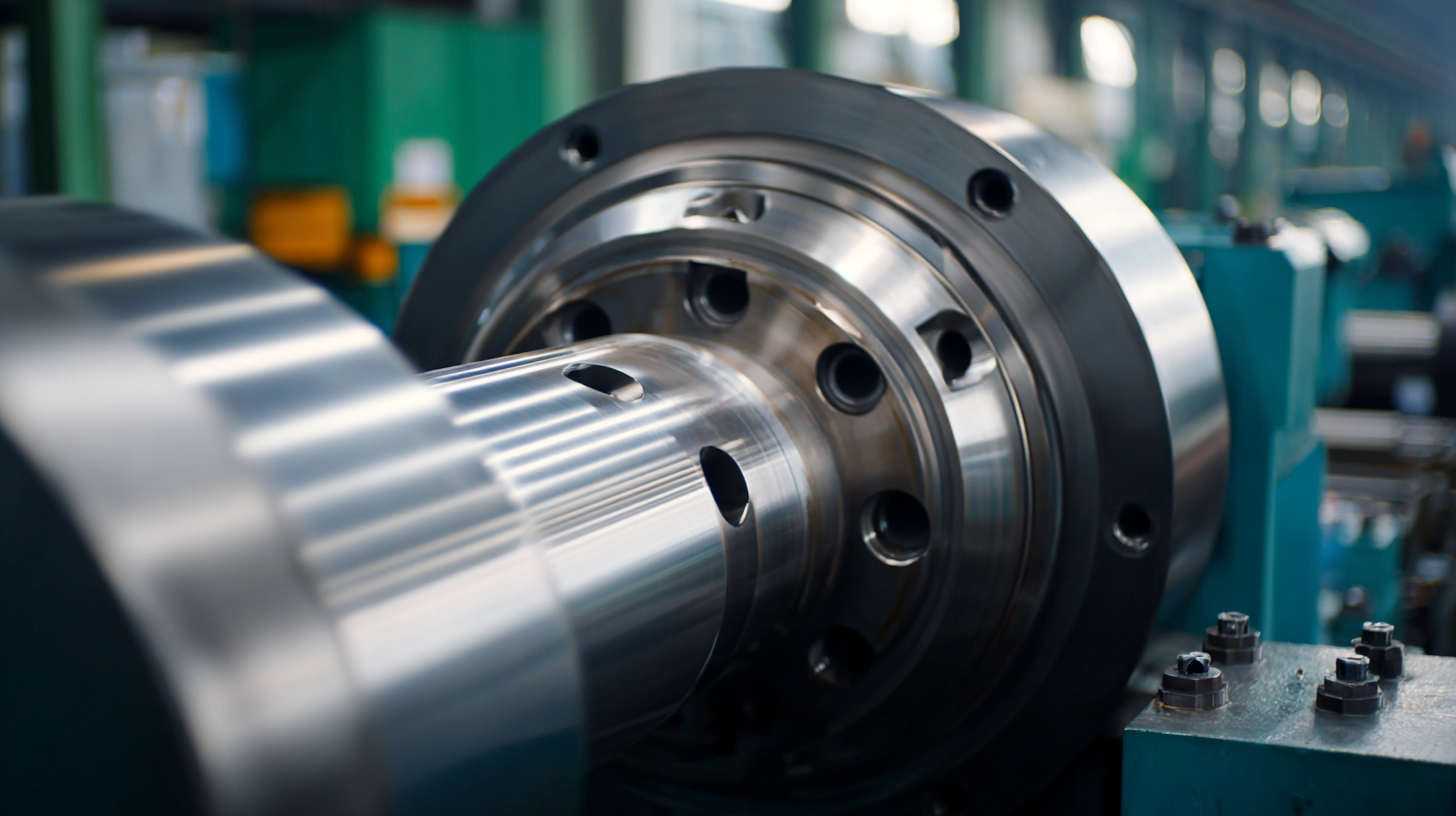

The integration of bucket cylinder technology into manufacturing processes is revolutionizing energy efficiency across various industries. Recent studies have shown that the innovative designs of bucket cylinders can enhance performance by reducing energy consumption by up to 30%. This is primarily achieved through advanced hydraulic configurations and optimized material usage, allowing for greater operational efficiency while minimizing waste.

The ability of bucket cylinders to provide precise force control further contributes to lower energy requirements, positioning them as a key component in sustainable manufacturing practices.

The integration of bucket cylinder technology into manufacturing processes is revolutionizing energy efficiency across various industries. Recent studies have shown that the innovative designs of bucket cylinders can enhance performance by reducing energy consumption by up to 30%. This is primarily achieved through advanced hydraulic configurations and optimized material usage, allowing for greater operational efficiency while minimizing waste.

The ability of bucket cylinders to provide precise force control further contributes to lower energy requirements, positioning them as a key component in sustainable manufacturing practices.

Tip: When considering bucket cylinder implementation, evaluate the benefits of variable displacement pumps, which can significantly reduce energy overhead by adjusting power according to actual load requirements.

Moreover, the continuous evolution in bucket cylinder design emphasizes lightweight materials, such as high-strength composites, which not only improve the cylinders' durability but also decrease the amount of energy needed for their operation. With industry reports highlighting that improved equipment efficiency leads to potential cost savings of around 15% annually, investing in modern bucket cylinder technology is proving to be a financially sound decision for manufacturers.

Tip: Regular maintenance and timely upgrades of hydraulic systems can prolong the life of bucket cylinders and sustain energy savings, ensuring that investments in energy efficiency yield long-term benefits.

The integration of the Internet of Things (IoT) with bucket cylinder systems marks a significant advancement in smart industrial operations. According to a report by MarketsandMarkets, the global IoT in manufacturing market is projected to grow from $40.5 billion in 2020 to $70.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 11.0%. This trend underscores the rising importance of data-driven decision-making, where bucket cylinder systems equipped with IoT technology offer real-time monitoring and predictive maintenance capabilities. These advancements not only enhance operational efficiency but also minimize downtime and reduce maintenance costs.

Moreover, the ability to collect and analyze data from bucket cylinder systems allows industries to optimize their processes. For instance, as businesses integrate sensors and connectivity into their hydraulic systems, they can track performance metrics and identify inefficiencies. A study by McKinsey highlights that industrial machinery players can increase their profitability by as much as 30% by adopting smart technologies, including IoT-enabled bucket cylinders. This shift toward interconnected systems signals a new era in automation, driving both productivity and sustainability across various sectors such as construction, manufacturing, and logistics.