+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

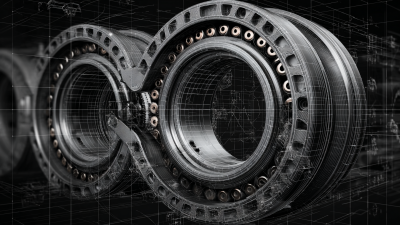

In the realm of modern heavy machinery, slewing rings have emerged as a crucial component influencing operational efficiency and safety. Defined as large bearings that enable rotational movement, slewing rings are vital in applications ranging from cranes and excavators to wind turbine installations.

The global slewing ring market is projected to witness significant growth, with a report by Market Research Future estimating an increase from USD 1.3 billion in 2020 to USD 2.2 billion by 2027, reflecting a compound annual growth rate (CAGR) of over 8%. This surge is driven by the heightened demand for advanced machinery across various industries, including construction, mining, and renewable energy.

As industries increasingly recognize the importance of reliability and precision in their equipment, the adoption of technologically advanced slewing rings is expected to play a pivotal role in facilitating industry growth and enhancing operational capabilities.

The global slewing ring market is projected to witness significant growth, with a report by Market Research Future estimating an increase from USD 1.3 billion in 2020 to USD 2.2 billion by 2027, reflecting a compound annual growth rate (CAGR) of over 8%. This surge is driven by the heightened demand for advanced machinery across various industries, including construction, mining, and renewable energy.

As industries increasingly recognize the importance of reliability and precision in their equipment, the adoption of technologically advanced slewing rings is expected to play a pivotal role in facilitating industry growth and enhancing operational capabilities.

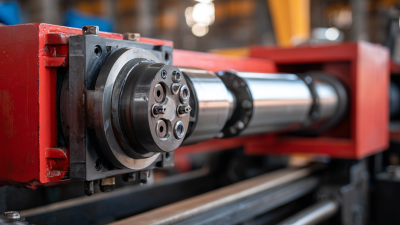

Slewing rings play a crucial role in enhancing the efficiency of heavy machinery by allowing for smooth rotation and movement of equipment components. As key components in cranes, excavators, and material handlers, slewing rings enable these machines to operate with precision and reliability. The integration of slewing rings significantly reduces wear and tear, promotes safety, and increases productivity by allowing for uninterrupted operations, even under heavy loads. This efficiency is vital, particularly in industries experiencing substantial growth, such as construction and demolition, where optimal performance directly impacts project timelines and costs.

In the context of the broader bearings market, which is projected to reach USD 97.10 billion, the demand for slewing rings is expected to follow suit. As industries strive for faster and more efficient processes through digitalization and networking, the importance of these components in enhancing equipment efficiency becomes even more pronounced. Companies are increasingly recognizing the value that slewing rings add to their machinery, leading to a push for advancements in bearing technology that further improve capabilities and performance in heavy machinery applications.

Slewing rings are becoming increasingly vital in various modern applications across key industries, driven by the growing demand for efficiency and reliability. Industries such as construction and renewable energy are particularly influential in this trend. The wind energy sector, for example, is experiencing a surge in demand for pre-assembled main bearing units. This shift reflects the industry's desire to minimize complexity and enhance operational reliability, thereby maximizing energy generation and reducing maintenance downtime. Reports indicate that slewing rings play a crucial role in the functionality and longevity of wind turbine operations, which are projected to grow significantly as the world shifts towards sustainable energy solutions.

Additionally, the manufacturing landscape is witnessing significant investments and expansions, particularly in countries like India, where local companies are innovating in the bearing sector. The establishment of new manufacturing facilities for slewing bearings by global industrial players underscores the burgeoning market. With estimates suggesting that the slewing ring market could grow at a compound annual growth rate (CAGR) of over 5% in the coming years, companies are racing to enhance their product offerings, including lightweight and customizable solutions leveraging advanced technologies like 3D printing. This innovation not only addresses the evolving requirements of heavy machinery but also aligns with the broader trends of industrial growth and sustainability.

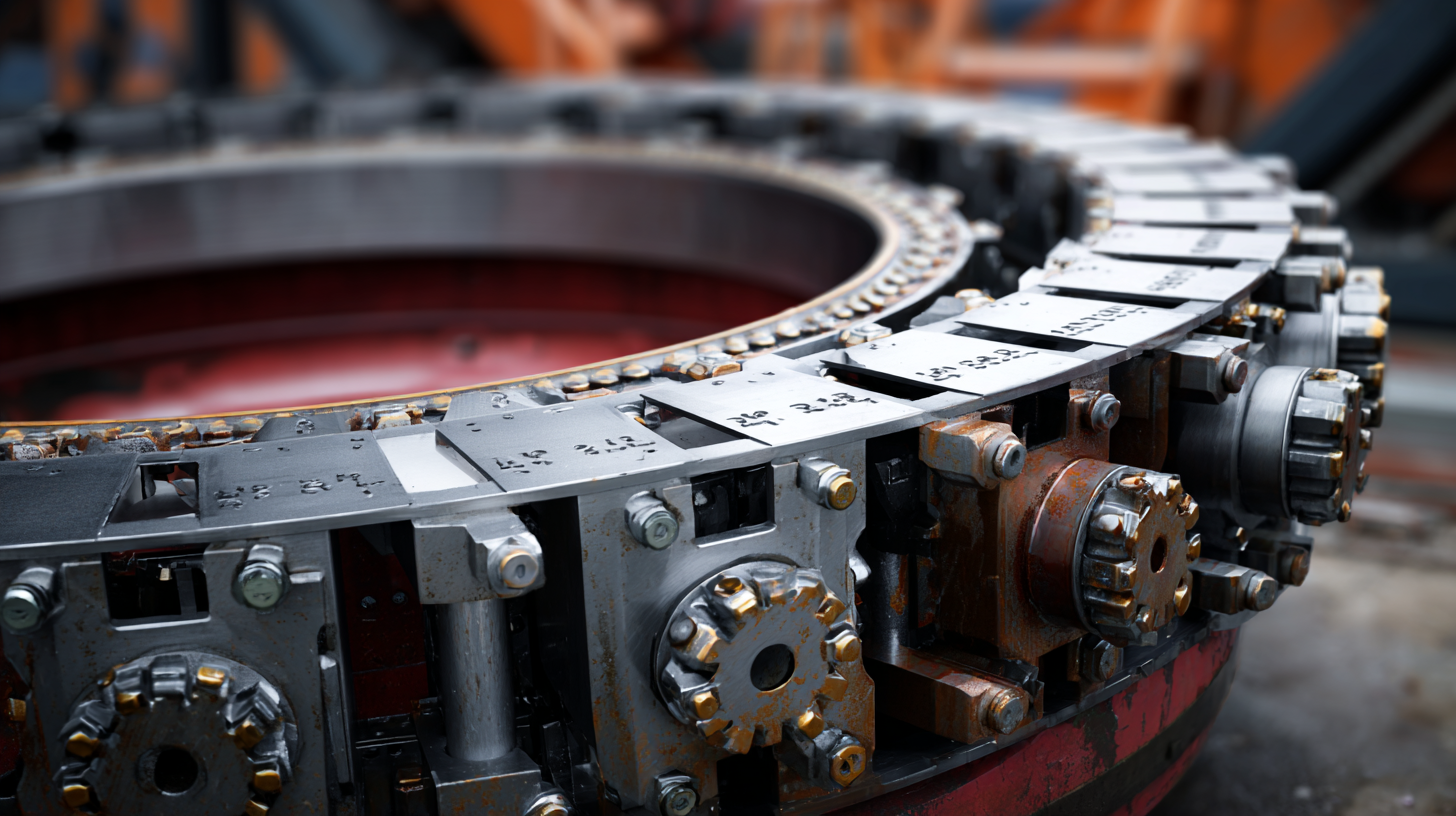

Slewing rings are essential components in heavy machinery, offering pivotal advantages in various applications, particularly in tower cranes. The comparative analysis of slewing ring technologies reveals significant differences in design, materials, and operational efficiency. For instance, advanced slewing rings provide enhanced load capacity and durability, which are critical for cranes operating in demanding environments. The adoption of high-performance slewing rings enables machinery to achieve superior stability and precision, directly impacting productivity and safety on construction sites.

Slewing rings are essential components in heavy machinery, offering pivotal advantages in various applications, particularly in tower cranes. The comparative analysis of slewing ring technologies reveals significant differences in design, materials, and operational efficiency. For instance, advanced slewing rings provide enhanced load capacity and durability, which are critical for cranes operating in demanding environments. The adoption of high-performance slewing rings enables machinery to achieve superior stability and precision, directly impacting productivity and safety on construction sites.

As the global bearings market continues to expand, projected to grow from USD 50.16 billion in 2025 to USD 97.10 billion by 2032, the role of slewing rings within this sector becomes increasingly prominent. Industries are gravitating toward modern slewing ring solutions that incorporate innovative materials, such as composite and low-friction coatings, improving overall machinery performance. This trend not only reflects the evolving demands of the construction industry but also underscores the technological advancements driving growth and efficiency in heavy machinery applications.

The future of slewing rings is poised for transformative innovations that could significantly enhance the capabilities and efficiency of heavy machinery. As industries increasingly adopt automation and smart technologies, slewing rings are becoming integral components in advanced machinery applications. Innovations, such as the integration of IoT sensors within slewing rings, allow for real-time monitoring of performance metrics. This capability not only promotes predictive maintenance but also minimizes downtime, making it a game-changer for operators in sectors like construction, mining, and manufacturing.

Additionally, the development of lightweight materials and advanced lubrication systems is set to revolutionize slewing ring design. By reducing the weight of slewing rings while maintaining structural integrity, manufacturers can improve the overall performance of machinery. This shift will facilitate the design of more agile and energy-efficient machines, catering to the growing demand for sustainable practices in heavy industry. As these trends unfold, slewing rings are likely to continue playing a pivotal role in driving innovation and efficiency within the heavy machinery landscape.

| Dimension | Description | Current Market Trends | Future Innovations |

|---|---|---|---|

| Material Quality | High-grade steel and composites for durability | Increased demand for high-strength materials due to operational challenges | Developments in lightweight alloys and advanced composites |

| Size and Load Capacity | Varied sizes designed for different machinery applications | Growing need for larger slewing rings as machinery size increases | Innovations for higher load capacities and more compact designs |

| Lubrication Systems | Integrated lubrication for reduced wear | Shift towards automatic lubrication solutions | Smart lubrication systems using IoT technology |

| Maintenance Practices | Scheduled checks to ensure optimal performance | Increasing focus on predictive maintenance | AI and machine learning for maintenance forecasting |

| Customization | Tailored designs for specific machinery | Higher demand for customized solutions in niche markets | 3D printing technology for bespoke manufacturing |

Slewing rings are pivotal components in modern heavy machinery, but they face several maintenance challenges that can impact their performance and longevity. One of the primary issues is wear and tear caused by the constant load and movement during operation. Over time, the internal elements of a slewing ring can degrade, leading to increased friction and potential failure. Effective lubrication practices and regular inspections are crucial in mitigating these effects, but these processes can often be overlooked in busy industrial settings.

Slewing rings are pivotal components in modern heavy machinery, but they face several maintenance challenges that can impact their performance and longevity. One of the primary issues is wear and tear caused by the constant load and movement during operation. Over time, the internal elements of a slewing ring can degrade, leading to increased friction and potential failure. Effective lubrication practices and regular inspections are crucial in mitigating these effects, but these processes can often be overlooked in busy industrial settings.

Another significant challenge stems from the environmental conditions in which these machines operate. Exposure to debris, moisture, and extreme temperatures can accelerate the degradation of slewing rings. Implementing protective covers and using seals can help prevent contaminants from infiltrating the mechanism. Furthermore, training operators on best practices for maintenance can improve the lifespan of slewing rings, ensuring that they function efficiently in demanding applications. By focusing on proactive maintenance strategies, industries can not only address existing challenges but also pave the way for sustainable growth in heavy machinery applications.