+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

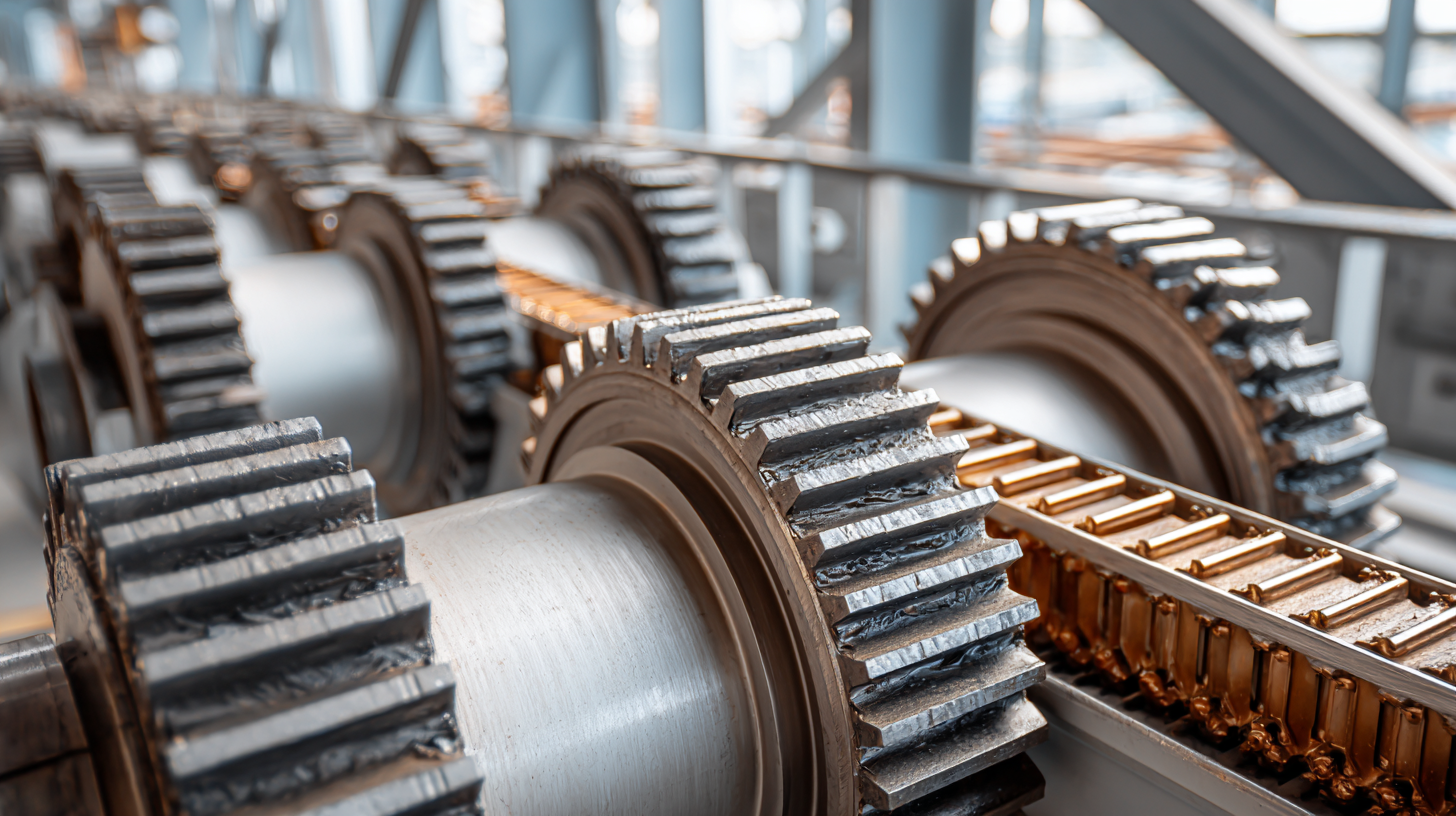

Slewing bearings play a crucial role in modern industrial applications, serving as a key component in machinery that require high precision and reliability. As industries continue to evolve, the demand for advanced slewing bearings has surged, with the global market projected to reach approximately $2.2 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026, according to a recent industry report. These bearings are integral in a variety of sectors, including construction, aerospace, and renewable energy, where they facilitate the smooth rotation and stability of heavy equipment and machinery. By understanding the impact and functionality of slewing bearings, industries can enhance operational efficiency, minimize maintenance costs, and improve the longevity of their equipment, ultimately driving productivity in a competitive landscape.

Slewing bearings are crucial components in heavy machinery operations, especially in applications that require a rotational movement. With the global bearings market projected to reach USD 97.10 billion by 2030, the significance of these bearings cannot be overstated. The efficiency, safety, and longevity they provide are vital in industries such as construction, offshore operations, and aerospace. For instance, companies incorporating advanced slewing solutions are better positioned to improve operational performance due to enhanced durability and precise movement control.

Tip: To maximize the lifespan of slewing bearings, regular maintenance and monitoring for wear and tear is essential. Implementing digital solutions for tracking performance can significantly reduce the risk of unexpected downtime and costly repairs.

The application of slewing bearings extends beyond typical use in cranes; they are increasingly utilized in complex machinery that requires reliable rotation. The demand for large-scale bearing solutions is on the rise, expected to grow at a CAGR of 6.1% by 2035, emphasizing the critical nature of these components in modern industrial applications. As industries evolve, the need for innovative bearing technology will prove even more integral to operational success.

Tip: Investing in high-quality slewing bearings from reputable manufacturers can enhance operational efficiency and reduce total cost of ownership over time.

Slewing bearings play a crucial role in modern industrial applications, particularly in renewable energy sectors where their benefits are becoming increasingly evident. The global bearings market, which was valued at USD 46.82 billion in 2024, is projected to grow significantly, reaching USD 50.16 billion in 2025 and soaring to an estimated USD 97.10 billion by 2035. This uptick highlights not just an increase in demand for standard bearings, but also a rising need for high-performance components like slewing bearings that can withstand diverse and challenging conditions found in renewable energy systems.

In renewable energy applications, slewing bearings enhance the operational efficiency of wind turbines and solar trackers. For example, mobile solar trackers benefit from slewing bearings' ability to allow for smooth movement and precise positioning, enabling solar panels to follow the sun's trajectory for optimal energy capture. As the global large-scale bearing market is expected to reach USD 20.42 billion in 2025, with a compound annual growth rate of 6.1%, it is evident that slewing bearings will play a pivotal role in driving advancements in this field, ensuring that renewable energy technologies are both efficient and sustainable.

Slewing bearings play a crucial role in the advancement of robotics and automation systems, serving as key components that support complex movements and precise positioning. In modern industrial applications, these bearings enable machines to operate with greater accuracy and efficiency. Their ability to handle heavy loads while allowing for continuous rotation makes them indispensable in applications ranging from assembly lines to robotic arms, enhancing productivity and operational flexibility.

As the global demand for automation rises, the slewing bearing market is expected to experience significant growth, driven by innovation and technological advancements. With a projected increase from USD 50.16 billion in 2025 to USD 97.10 billion, manufacturers are continuously seeking improvements in bearing design and materials to cater to the evolving requirements of robotics. This growth reflects the increasing reliance on slewing bearings in industries such as manufacturing, aerospace, and construction, where high performance and reliability are essential for the efficiency of automated systems. As robotics continue to shape the future of industrial applications, the importance of slewing bearings will undoubtedly become more pronounced.

Slewing bearings play a critical role in modern industrial applications, particularly in sectors like construction, mining, and renewable energy. However, the technology presents various challenges, including the need for enhanced load capacity, durability, and efficiency. According to a report from MarketsandMarkets, the global slewing bearing market is projected to grow from $3.2 billion in 2022 to $4.5 billion by 2027, driven by increasing demand for heavy machinery and advanced construction equipment.

Innovations in slewing bearing technology are addressing these challenges through advanced materials and design methodologies. For instance, manufacturers are now utilizing high-strength steel and polymer composites to improve longevity and reduce weight. A recent analysis by Grand View Research highlighted that the adoption of computer-aided design (CAD) in slewing bearing development has significantly enhanced precision and performance. Additionally, the integration of IoT technology within slewing bearings enables real-time monitoring, which can lead to predictive maintenance and reduced downtime. This combination of innovative materials and smart technology is positioning slewing bearings as vital components for future industrial advancements.

The future trends in slewing bearing applications are increasingly being shaped by technological advancements and the growing demand for efficiency across various industries. Slewing bearings play a crucial role in modern machinery and equipment, particularly in sectors such as construction, renewable energy, and manufacturing. As industries evolve, the need for more compact, lightweight, and durable bearings becomes paramount. Innovations such as digital solutions for monitoring wear and advanced materials are enhancing the performance and longevity of slewing bearings.

Moreover, the sustainability push in industrial applications is prompting manufacturers to design slewing bearings that not only meet performance standards but also adhere to environmentally friendly practices. The rising emphasis on automation and smart technologies further drives the integration of slewing bearings in sophisticated machinery. As the global bearing market is projected to expand significantly in the coming years, the adaptability of slewing bearings will be essential in addressing the challenges posed by changing market dynamics and consumer expectations.