+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

In modern industrial applications, the ability to efficiently lift heavy loads is paramount, and hydraulic lift cylinders play a crucial role in this process. According to a report by the International Fluid Power Society, hydraulic systems account for approximately 40% of the lifting equipment market, emphasizing their importance in enhancing productivity and reducing labor costs. The mechanical principles governing hydraulic lift cylinders are integral to understanding their performance, as they utilize hydraulic pressure to generate significant lifting capabilities with minimal effort. By delving into the mechanics of these cylinders, industries can optimize their lifting operations, ensuring reliability and efficiency. As technology advances, the development of high-efficiency hydraulic lift cylinders continues to reshape the landscape of material handling, paving the way for innovations that promise even greater performance and sustainability.

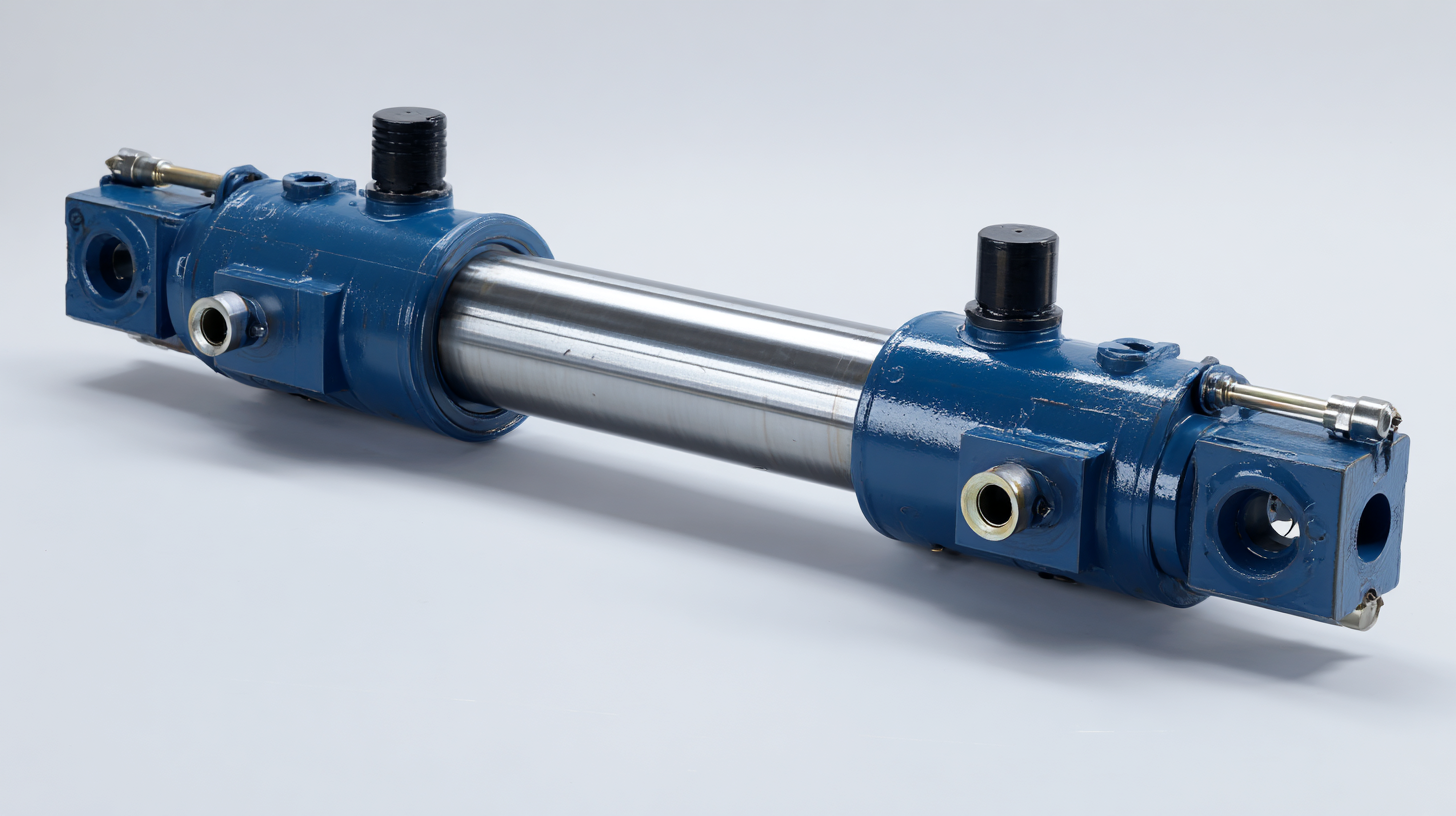

When selecting a hydraulic lift cylinder, understanding the specific requirements of your application is crucial. The key factors to consider include the load capacity, stroke length, and working pressure. Different industries might demand cylinders with unique features; for instance, a construction site may require a heavy-duty cylinder that can withstand harsh conditions, while a small automotive workshop might need a compact model for lighter lifting tasks. Evaluating the workspace and the load specifications will help narrow down the options available.

Another important consideration is the type of hydraulic fluid used and the compatibility of the cylinder with your existing equipment. Some hydraulic systems operate at higher pressures, which necessitates a cylinder that can handle such demands without compromising safety or performance. Additionally, factors like temperature range and environmental conditions can affect the cylinder's longevity and efficiency. Ultimately, thorough research and consultation with manufacturers can guide you in choosing the right hydraulic lift cylinder that matches both your operational needs and performance expectations.

This chart illustrates the lifting capacities of various hydraulic lift cylinders, demonstrating their performance based on tonnage classes. Selecting the right hydraulic lift cylinder depends on the specific lifting needs, which this visual aid effectively conveys.

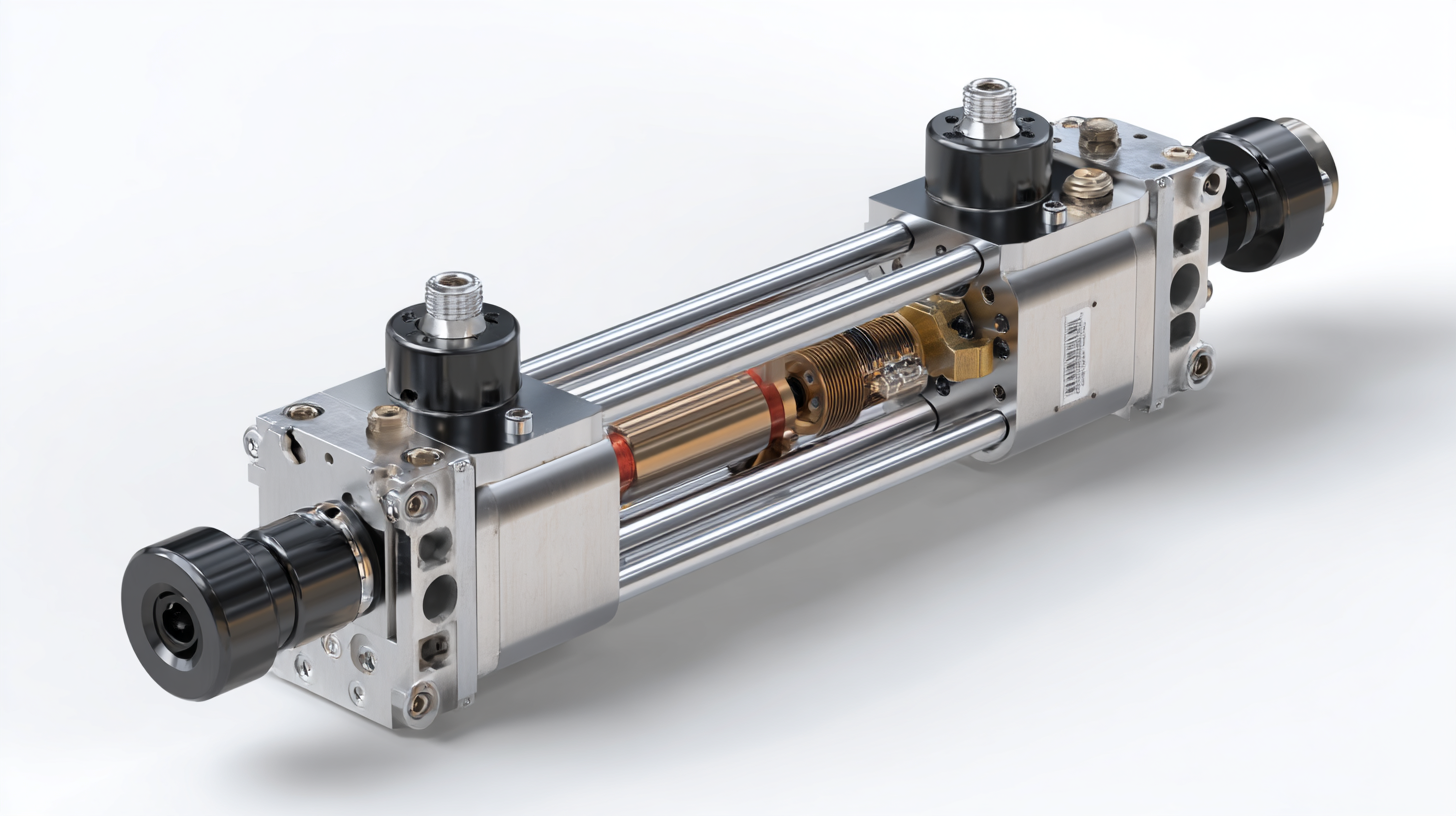

Hydraulic lift cylinders are integral to the functionality and efficiency of various lifting systems. At the heart of these cylinders are several essential components that contribute to their overall performance. The cylinder itself is typically made from robust materials designed to withstand high pressures, ensuring durability and reliability under heavy loads. Inside, hydraulic fluid is housed, which transfers power from the pump to the lifting mechanism. The precision-engineered piston moves within the cylinder powered by this fluid, creating the force necessary for lifting operations.

Another crucial element is the seals that prevent fluid leakage and maintain hydraulic pressure. These seals are vital for ensuring the efficiency of the system and avoiding costly repairs. The connecting rods and valves also play significant roles; the rods transmit force between the piston and the load, while the valves control the flow direction and pressure of the hydraulic fluid. Understanding these components allows for better maintenance and optimization of hydraulic lift cylinders, enhancing their performance and extending their lifespan in lifting applications.

Maintaining hydraulic lift cylinders is essential for ensuring optimal performance and longevity of lifting equipment. According to industry reports, routine maintenance can reduce unexpected failures by up to 30%, significantly lowering operational costs. Keeping hydraulic systems clean and free of contaminants is critical, as dirty hydraulic fluids can lead to wear and degradation of cylinder components. Regular inspection of seals and hoses, along with timely replacement, is advised to prevent leaks that can compromise lifting efficiency.

Tips for Maintenance: Always check fluid levels and quality; replace fluids that show signs of contamination annually. Additionally, regular pressure testing can help identify any weaknesses in the system before they lead to costly breakdowns.

Another important aspect of maintenance is the lubrication of sliding parts. A well-lubricated hydraulic lift cylinder not only operates more efficiently but also extends its lifespan. According to the Fluid Power Journal, properly maintained hydraulic systems can improve energy efficiency by an estimated 15%. Therefore, implementing a comprehensive maintenance schedule that includes lubrication can have a significant impact on overall performance and reliability.

Tips for Efficiency: Utilize high-quality lubricants that are compatible with your hydraulic fluid to enhance protection and performance. Always follow the manufacturer's recommendations for maintenance intervals and practices to ensure optimal operation.

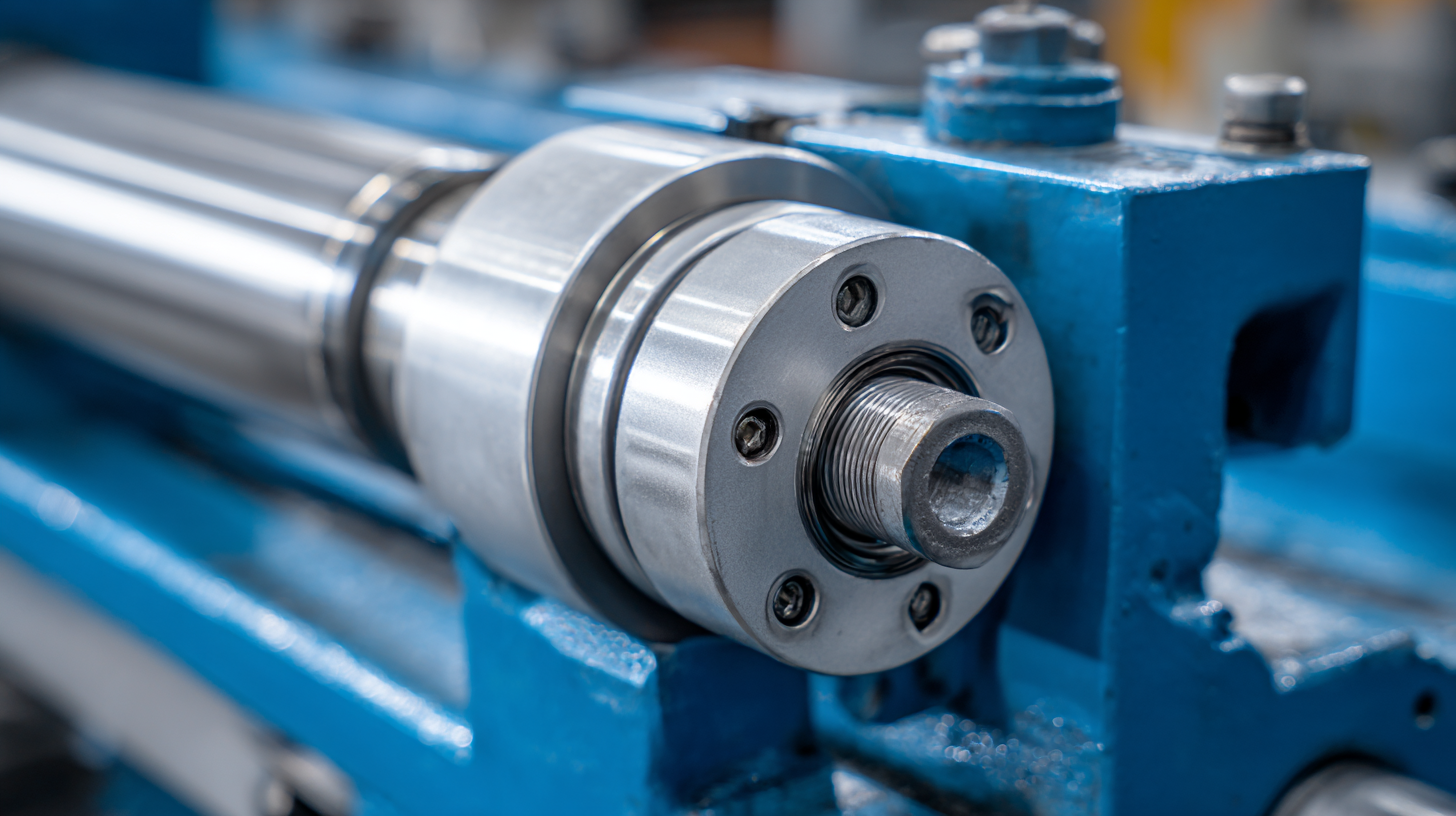

Hydraulic lift cylinders play a crucial role in various lifting applications, but they can encounter issues that hinder performance. One common problem is hydraulic leaks, which can significantly reduce lifting efficiency. Regularly inspecting hoses, seals, and connections for wear and damage is essential. If a leak is detected, it is crucial to replace those components promptly to maintain optimal performance.

Another frequent issue is cylinder sticking, often caused by contamination in the hydraulic fluid or rust buildup. Sticking can prevent the cylinder from extending or retracting smoothly. To troubleshoot this problem, ensure the hydraulic fluid is clean and free from debris. If rust is a concern, consider using a rust remover and regularly lubricating moving parts to prevent future sticking.

**Tip:** Always maintain a clean hydraulic system by replacing the fluid as recommended and using filters to catch any contaminants. Additionally, routinely check the cylinder's alignment to ensure it operates efficiently without added strain. By addressing these common issues, you can enhance the performance and longevity of your hydraulic lift cylinders.

Hydraulic lift cylinders operate on the principle of fluid dynamics, which plays a crucial role in determining the efficiency of lifting operations. The movement of hydraulic fluid through the cylinders generates force, enabling heavy objects to be raised with ease. Understanding how fluid properties, such as viscosity and pressure, influence this process can lead to better performance and reliability of lifting systems. By optimizing these factors, operators can enhance operational speed and reduce energy consumption, ultimately improving overall productivity.

Tip: Regular maintenance of hydraulic systems is essential for preserving fluid quality and ensuring proper functioning. Check fluid levels and replace fluids as necessary to prevent degradation, which can affect lifting capacity.

Moreover, the design of hydraulic lift cylinders must accommodate fluid flow dynamics to minimize resistance and maximize lift efficiency. This involves selecting the right cylinder size and ensuring smooth internal surfaces for fluid passage. Understanding the relationship between fluid velocity, pressure, and lifting force helps in selecting appropriate components that can significantly improve lifting performance across various applications.

Tip: Consider using advanced simulation tools to analyze fluid dynamics in your design phase. This can help identify potential inefficiencies before implementing hydraulic systems.