+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

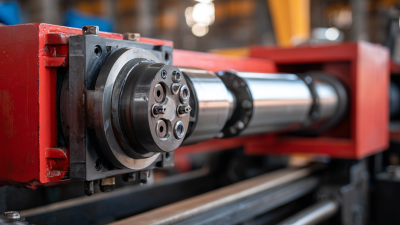

Choosing the right Bucket Cylinder for your hydraulic needs is a critical decision that can significantly impact the efficiency and effectiveness of your operations. According to hydraulic systems expert, Dr. Jane Thompson, "Selecting the appropriate Bucket Cylinder is not just about size; it's about matching the performance requirements with the specific application." This insight highlights the importance of understanding both the technical specifications and operational demands when making your choice.

In various industries, from construction to agriculture, the performance of a Bucket Cylinder can greatly influence productivity and safety. As such, knowing what features to look for and which questions to ask is crucial for ensuring you select the right component for your hydraulic system. Whether you are replacing an old cylinder or investing in new equipment, understanding the essential tips for choosing the right Bucket Cylinder will empower you to make informed decisions that align with your operational goals. Let's delve into the top ten considerations that can guide you in this crucial selection process.

When selecting a bucket cylinder for your hydraulic needs, understanding the various types available and their specific applications is crucial. Bucket cylinders typically fall into categories such as single-acting and double-acting cylinders. Single-acting cylinders are used in scenarios where the load is lowered by gravity, making them ideal for simple applications like tilting mechanisms. On the other hand, double-acting cylinders can exert force in both directions, providing greater control and efficiency for more complex operations, such as lifting and positioning in construction and manufacturing settings.

According to a report from MarketsandMarkets, the hydraulic cylinder market is expected to grow from USD 15.4 billion in 2020 to USD 20.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.7%. This growth is fueled by the increasing demand for hydraulic systems in various industries, including agriculture, construction, and marine. Different applications necessitate specific features, such as bore size, stroke length, and mounting type, to ensure optimal performance and longevity. Understanding these nuances can significantly impact the efficiency and reliability of hydraulic operations, making it essential for professionals to choose the right bucket cylinder tailored to their application's demands.

When selecting a hydraulic cylinder, understanding key specifications is crucial for ensuring optimal performance and longevity. One major factor to consider is the cylinder's bore size, which directly influences the power and speed of the hydraulic system. According to the Fluid Power Journal, cylinders with larger bores can deliver higher force outputs but may require more fluid, impacting system efficiency. Choosing the appropriate bore based on the specific application is essential; for instance, smaller bore sizes are often suitable for applications requiring precision, while larger sizes are ideal for heavy-duty tasks.

Another critical specification to evaluate is the port size and configuration. Proper port sizing ensures adequate flow rates and minimizes turbulence, which can lead to inefficiencies. A report from the International Fluid Power Society indicates that improper port sizing can decrease the system's overall performance by up to 30%. Additionally, consider the pressure rating of the hydraulic cylinder, as it must align with your system's operational pressure. It's important to select a cylinder that can withstand the maximum pressure expected during operation, ensuring both safety and reliability in demanding applications.

When selecting the right bucket cylinder for hydraulic applications, the material and durability of the cylinder play a crucial role in ensuring reliability and performance. Bucket cylinders are often subjected to extreme conditions, including high pressure, temperature variations, and abrasive environments. Therefore, choosing a cylinder made from high-quality materials, such as carbon steel or stainless steel, can significantly enhance its longevity and resistance to wear.

When selecting the right bucket cylinder for hydraulic applications, the material and durability of the cylinder play a crucial role in ensuring reliability and performance. Bucket cylinders are often subjected to extreme conditions, including high pressure, temperature variations, and abrasive environments. Therefore, choosing a cylinder made from high-quality materials, such as carbon steel or stainless steel, can significantly enhance its longevity and resistance to wear.

Additionally, evaluating the cylinder's design and protective coatings is essential for maximizing durability. Cylinders with improved sealing systems can prevent contamination from hydraulic fluids, reducing the risk of failure and maintenance costs. Assessing the manufacturer's specifications regarding load capacity and corrosion resistance will further aid in ensuring that the selected bucket cylinder meets the demands of your specific hydraulic needs, ultimately contributing to more efficient operational outcomes.

When selecting a bucket cylinder for hydraulic applications, ensuring compatibility with existing hydraulic systems is paramount. The hydraulic system's pressure ratings, flow rates, and size dimensions must align with the chosen cylinder to maintain operational efficiency. Industry reports indicate that improper compatibility can lead to performance issues, such as inadequate lifting capacity or even catastrophic failures. According to the Hydraulic Manufacturers Association, nearly 30% of hydraulic system failures can be traced back to incompatible components and inadequate system design.

Additionally, evaluating the cylinder's materials and seal compatibility is crucial. A report from the International Fluid Power Society highlights that over 40% of hydraulic failures result from seal degradation caused by chemical incompatibility or material fatigue. This emphasizes the need for thorough examination and testing of existing systems before procurement. Ensuring that the new bucket cylinder aligns with both the technical specifications and environmental conditions of current hydraulic systems can significantly enhance longevity and reliability, ultimately reducing the total cost of ownership and downtime for operators.

| Tip Number | Tip Description | Importance Level | Compatibility Factors |

|---|---|---|---|

| 1 | Understand Load Requirements | High | Weight capacity and application |

| 2 | Check Hydraulic Pressure Ratings | Critical | System compatibility and pressure limits |

| 3 | Select Appropriate Cylinder Size | High | Space constraints and function |

| 4 | Consider Material and Construction | Medium | Corrosion resistance and durability |

| 5 | Evaluate Stroke Length | High | Operational requirements |

| 6 | Inspect Mounting Options | Medium | Compatibility with existing hardware |

| 7 | Check Compatibility with Existing Systems | Critical | Hydraulic fluid type and system configuration |

| 8 | Assess Sealing Options | Medium | Leakage prevention and maintenance needs |

| 9 | Review Manufacturer Guidelines | High | Proper usage and maintenance protocols |

| 10 | Plan for Future Upgrades | Medium | Scalability and adaptability |

When selecting the right bucket cylinder for your hydraulic needs, assessing performance metrics and operational efficiency is crucial. Performance metrics such as lifting capacity, stroke length, and cycle time should align with your specific applications. A bucket cylinder that meets or exceeds capacity requirements will enhance productivity, ensuring that operations run smoothly without overstraining the equipment. Additionally, monitoring cycle times can reveal inefficiencies in your existing setup, allowing for adjustments that can save both time and energy.

Tip 1: Choose a bucket cylinder with a reputable performance history. Research the manufacturer’s specifications and user reviews to understand how the cylinder performs in real-world conditions.

Tip 2: Evaluate the hydraulic fluid compatibility and temperature range of the cylinder. This assessment is essential for maintaining operational efficiency, as improper fluid or temperature can lead to wear and tear, compromising performance over time.

Incorporating these performance metrics into your selection process will not only optimize operational efficiency but will also ensure a longer lifespan for your hydraulic components.