+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

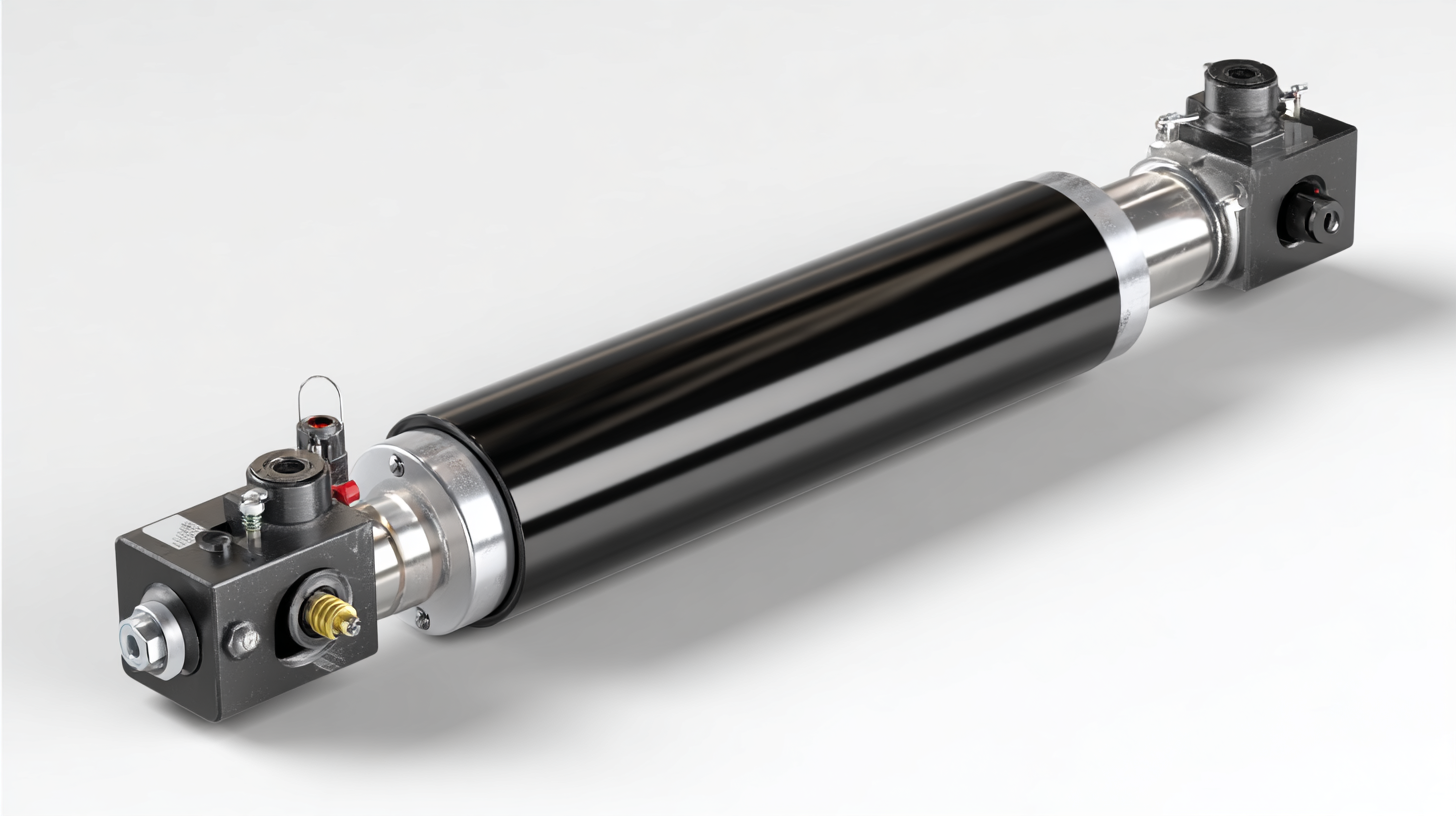

Selecting the right compact hydraulic cylinder for your project needs is a critical decision that can significantly impact the efficiency and effectiveness of your operations. Compact hydraulic cylinders are designed to provide high force in a smaller footprint, making them ideal for applications where space is limited. However, with several options available in the market, navigating through specifications, materials, and performance characteristics can be daunting. Understanding the key factors such as load capacity, stroke length, and environmental conditions is essential for making an informed choice. This guide aims to equip you with the necessary knowledge to assess your requirements and select the most suitable compact hydraulic cylinder. By following these insights, you can ensure optimal performance and reliability in your projects, ultimately enhancing productivity and achieving your engineering goals.

When selecting compact hydraulic cylinders for material handling applications, several key considerations must be taken into account to ensure optimal performance and efficiency. The shift toward compact hydraulic systems highlights the growing demand for hydraulic components that not only save space but also enhance productivity. According to market forecasts, the global hydraulics market is projected to grow from approximately $39.40 billion in 2025 to around $44.26 billion by 2030, indicating a strong trend towards the development of more efficient hydraulic solutions that meet the space and performance requirements of modern engineering applications.

One crucial aspect to consider is the integration of sensor technologies for hydraulic valve and system performance monitoring. These innovations address the challenges faced by hydraulic fluid power systems across various sectors such as transportation, heavy industry, and robotics. High-performance sensors can provide real-time data, allowing for proactive maintenance and improved system reliability. Furthermore, in material handling applications, the ability to maneuver compact hydraulic cylinders with precise control not only enhances operational efficiency but also contributes to safety and cost-effectiveness, particularly when coupled with pneumatic control methods that provide reliable and easy-to-manage operations in hydraulic systems.

This bar chart illustrates key considerations when selecting compact hydraulic cylinders for material handling applications. Key factors include bore size, stroke length, operating pressure, mounting options, and weight, helping you determine the optimal cylinder for your project needs.

When selecting a compact hydraulic cylinder for your project, understanding operating pressure ratings is essential to ensure efficiency and reliability. Hydraulic systems often operate under various pressures, typically ranging from 500 psi to as high as 5000 psi, depending on the application and design specifications. A critical aspect to consider is the pressure rating of the cylinder, which should align with the system’s operational requirements. For instance, a study by the International Journal of Fluid Power indicates that cylinders designed for higher pressure applications can withstand shock loads and dynamic stresses better, extending the lifespan of your equipment.

Furthermore, it’s important to consider the pressure drop that occurs within the hydraulic system. Data suggests that a 10% drop in pressure can significantly affect the performance of compact cylinders, leading to reduced efficiency and slower actuation speeds. When assessing the cylinder, ensure it is rated for the maximum expected pressure in your application, which should account for factors like temperature variations and fluid viscosity changes. Manufacturers often provide detailed specifications, and adhering to these ensures optimal operation under your specific project conditions, ultimately leading to better performance and lower maintenance costs.

| Cylinder Type | Bore Diameter (mm) | Stroke Length (mm) | Operating Pressure (bar) | Weight (kg) |

|---|---|---|---|---|

| Double-Acting Cylinder | 32 | 250 | 150 | 5.5 |

| Single-Acting Cylinder | 25 | 200 | 120 | 3.8 |

| Telescopic Cylinder | 40 | 300 | 200 | 7.2 |

| Rotary Cylinder | 50 | 180 | 160 | 6.0 |

| Compact Profile Cylinder | 20 | 150 | 110 | 2.5 |

When selecting a compact hydraulic cylinder for your project, one of the most critical considerations is the versatility of stroke length. The stroke length directly influences the range of motion and operational efficiency of the hydraulic system, making it essential to evaluate the specific demands of your application. A versatile stroke length enables the cylinder to accommodate varying tasks and spaces, particularly in confined environments where larger cylinders cannot function effectively.

Different applications require different stroke lengths; thus, assessing the maximum and minimum lengths needed for your project is crucial. A compact hydraulic cylinder that offers adjustable or numerous stroke length options can enhance flexibility, allowing it to adapt to different operational requirements without the need for replacing the component. Furthermore, understanding the implications of stroke length on the force output and overall system design will help in achieving optimal performance, ensuring that the hydraulic cylinder meets the precise needs of your application while maintaining efficiency and reliability.

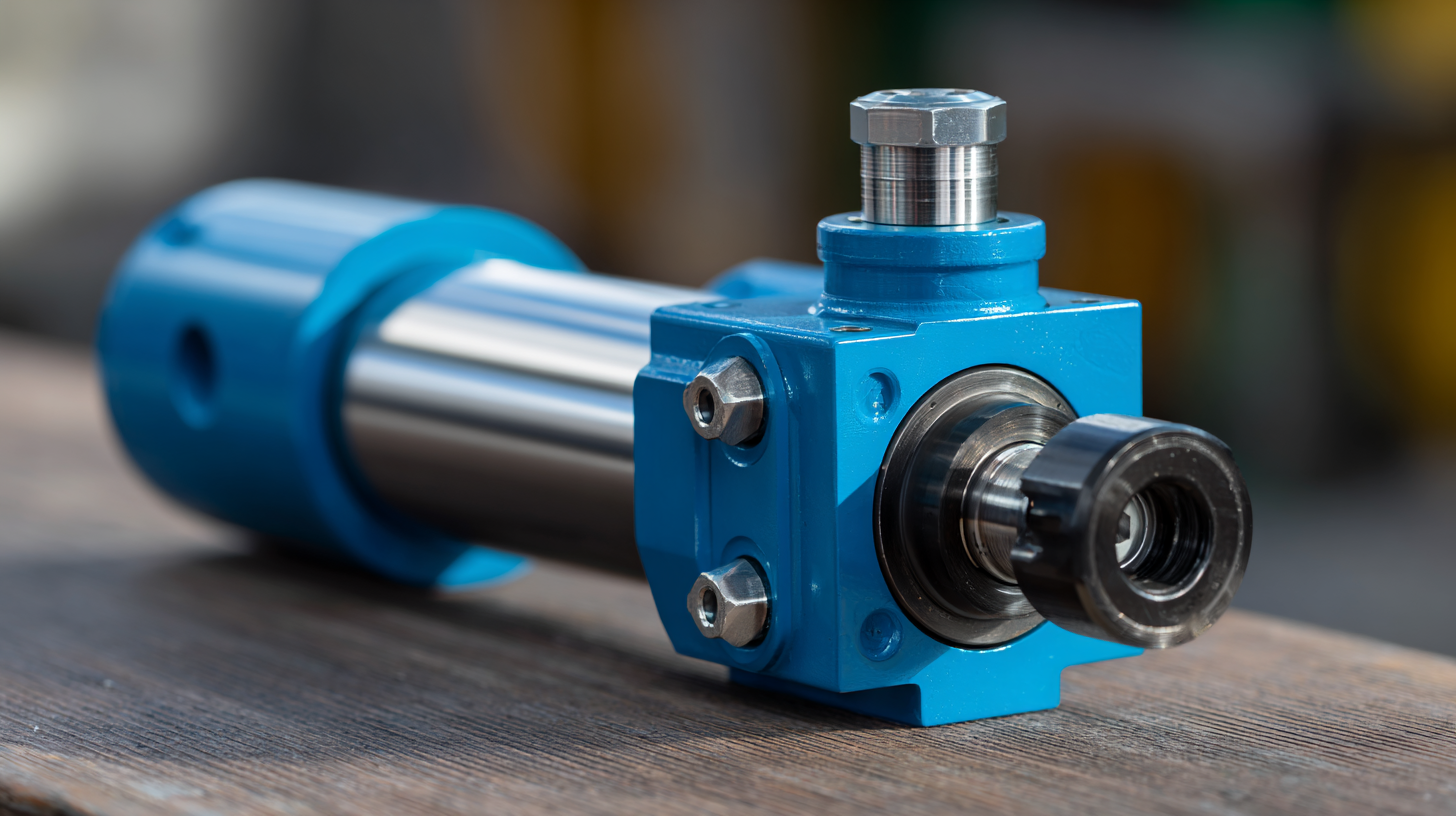

When selecting a compact hydraulic cylinder for projects with space constraints, it is essential to consider the various mounting options available. While conventional side or front mounting may suffice in many applications, unique environments often demand more innovative solutions. According to a recent report by the International Hydraulics Association, approximately 30% of hydraulic failures can be attributed to improper mounting, highlighting the critical nature of this selection process in ensuring both function and reliability.

A comparative analysis of cylinder mounting options reveals that configurations such as trunnion mounts and clevis mounts offer specific advantages for space-limited applications. Trunnion mounts provide a robust solution that allows for rotation around a central axis, accommodating greater flexibility in design while minimizing footprint. On the other hand, clevis mounts facilitate simpler installations, making them ideal for tighter spaces where assembly time is critical. A study published in the Journal of Fluid Mechanics indicates that optimizing mounting configurations can lead to efficiency improvements of up to 15%, significantly benefiting high-performance hydraulic systems in constrained environments.

When selecting a compact hydraulic cylinder for your project, environmental factors play a crucial role in determining performance and longevity. Factors such as temperature, humidity, and exposure to corrosive elements can profoundly impact the functionality of hydraulic systems. According to recent industry analyses, systems operating in extreme environments may experience a reduction in lifespan by up to 30% if unsuitable materials are utilized. This emphasizes the importance of assessing the operating environment before making a selection.

Tips for ensuring optimal performance include choosing cylinders made with materials resistant to corrosion and extreme temperatures, which can enhance durability. Moreover, incorporating hydraulic fluids designed for specific environmental conditions can improve efficiency and reduce maintenance costs over time. It is also advisable to utilize seals and protective coatings that can withstand harsh environments, minimizing wear and tear on critical components.

The ongoing trend toward sustainable engineering solutions, such as using advanced materials that lower carbon footprints, should not be overlooked. Research indicates that sustainable materials can enhance the overall performance of hydraulic systems while also addressing environmental concerns. By making informed material choices and understanding environmental impacts, you can significantly enhance the longevity and efficiency of your compact hydraulic cylinder.