+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

Choosing the right backhoe cylinder is essential for ensuring optimal performance and longevity in construction operations. Backhoe cylinders play a critical role in the functionality of heavy machinery, directly affecting productivity, efficiency, and the overall success of construction projects. From lifting and digging to pushing and pulling, the performance of these cylinders is paramount. However, selecting the appropriate cylinder involves various considerations, including the specific requirements of the task, the compatibility with existing equipment, and the desired durability under varying conditions. This article presents a comprehensive guide with numerical tips on how to effectively choose the best backhoe cylinder, ensuring that construction operations not only meet industry standards but also mitigate downtime and overall maintenance costs. Understanding these key factors will empower operators and decision-makers to make informed choices, leading to enhanced operational performance and prolonged equipment life.

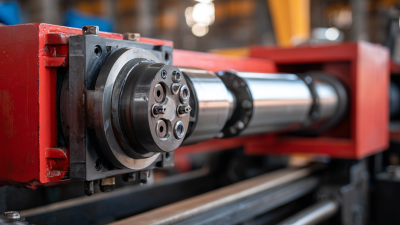

When selecting the right backhoe cylinder, understanding the various types and their specific functions is crucial for achieving optimal performance in construction operations. Backhoe loaders typically utilize three main types of hydraulic cylinders: the lift cylinder, the dipper cylinder, and the bucket cylinder. The lift cylinder is responsible for raising and lowering the loader's arms, while the dipper cylinder controls the movement of the backhoe's arm. The bucket cylinder, on the other hand, is essential for manipulating the bucket itself. Each cylinder must be chosen based on the load capacity and the specific task requirements, as improper selection can lead to decreased efficiency and increased wear.

Tips for selecting the right backhoe cylinder include assessing the load conditions and operating environment, as cylinders are not one-size-fits-all. According to industry reports, using the appropriate cylinder can improve overall machinery efficiency by up to 30%, significantly extending the lifespan of the equipment. Additionally, opting for high-quality materials designed to withstand hydraulic pressure will minimize the risk of failure, ensuring that operations run smoothly.

Furthermore, regular maintenance of backhoe cylinders is vital. Inspections should include checking for leaks, ensuring that seals are in good condition, and monitoring fluid levels. Studies show that proactive maintenance can reduce downtime by nearly 50%, leading to more productive construction operations. By understanding cylinder functions and adhering to these maintenance tips, construction professionals can ensure their backhoe equipment runs optimally for years to come.

When selecting the right backhoe cylinder for optimal performance and longevity, several key factors must be considered. Firstly, the size and specifications of the cylinder are crucial. This includes the bore diameter, stroke length, and rod diameter, as these dimensions directly affect the power and efficiency of your backhoe. Additionally, ensure that the cylinder's capacity matches the demands of your specific construction tasks, whether it be lifting heavy materials or precise digging.

Material quality is another significant consideration. Backhoe cylinders are typically subjected to harsh working conditions, so selecting cylinders made from high-strength steel or those with corrosion-resistant coatings can enhance durability. Furthermore, examining the seal design is essential, as high-quality seals prevent hydraulic fluid leakage and reduce wear, contributing to the longevity of the cylinder. Finally, compatibility with your backhoe model and the hydraulic system must be verified to promote seamless integration and optimal functionality.

This chart illustrates key attributes of backhoe cylinders that influence their performance and longevity in construction operations. The metrics include pressure rating, bore size, rod diameter, stroke length, and weight, all important considerations when selecting a backhoe cylinder.

When selecting the right backhoe cylinder for construction operations, evaluating

cylinder specifications is crucial for ensuring

optimal performance and longevity. The first step

is to consider the cylinder's bore diameter, which affects the lifting and digging capacity.

A larger bore diameter generally provides greater power but can also add weight and complexity

to the machine. It's essential to match the bore size with the specific tasks of your construction

project to achieve a balance between power and maneuverability.

To enhance the longevity of backhoe cylinders, regular maintenance is crucial. First and foremost, frequently inspect the cylinders for signs of wear, leaks, or damage. This involves checking the seals, rods, and barrel for any signs of deterioration. If any issues are detected early on, addressing them promptly can prevent more extensive damage and costly repairs down the line. Furthermore, keeping the cylinders clean from dirt and debris not only helps in maintaining their functionality but also preserves the integrity of the seals.

Another effective maintenance tip is to ensure proper lubrication. Applying the right grease at the recommended intervals helps reduce friction and wear on the moving parts, significantly extending the lifespan of the backhoe cylinders. Additionally, operators should be mindful of the operating conditions; avoiding extreme loads and using the backhoe within its specified limits can lead to improved performance and longevity. Taking the time to implement these maintenance strategies will not only optimize the backhoe cylinder's functionality but also ensure it remains a reliable asset in construction operations for years to come.

| Cylinder Size (inches) | Lift Capacity (lbs) | Bore Diameter (inches) | Stroke Length (inches) | Recommended Oil Type | Maintenance Frequency (months) |

|---|---|---|---|---|---|

| 4 | 5,000 | 2.5 | 20 | AW32 Hydraulic Oil | 6 |

| 6 | 8,000 | 3.0 | 24 | AW46 Hydraulic Oil | 6 |

| 8 | 10,000 | 4.0 | 30 | AW68 Hydraulic Oil | 12 |

| 10 | 12,000 | 5.0 | 36 | AW32 Hydraulic Oil | 12 |

Backhoe cylinders are crucial for the efficient operation of construction equipment, but they can encounter various issues that affect performance and reliability. Common problems include leakage, bending, and failure to extend or retract smoothly. Leakage is often caused by worn seals or damaged cylinder bodies, which can lead to reduced hydraulic pressure and compromised lifting capabilities. Regular inspections and timely seal replacements can mitigate these issues, ensuring optimal hydraulic performance and extending the lifespan of the equipment.

Another frequent issue is bending or misalignment, often a result of overloading or improper handling. This can cause further damage not only to the cylinder itself but also to the connected hydraulic system. To address this, operators should adhere to the manufacturer's weight guidelines and ensure that backhoes are used within their designed operational limits. Additionally, proper maintenance routines, including the regular checking of cylinder mounts and bushings, can help prevent these structural issues from arising. By being proactive and attentive, construction teams can overcome common backhoe cylinder problems, enhancing overall productivity on the job site.