+86-13349293098

+86-13349293098

Leave Your Message

-

Contact Phone

Contact Phone -

Contact WhatsApp

Contact WhatsApp -

Contact Email

Contact Email

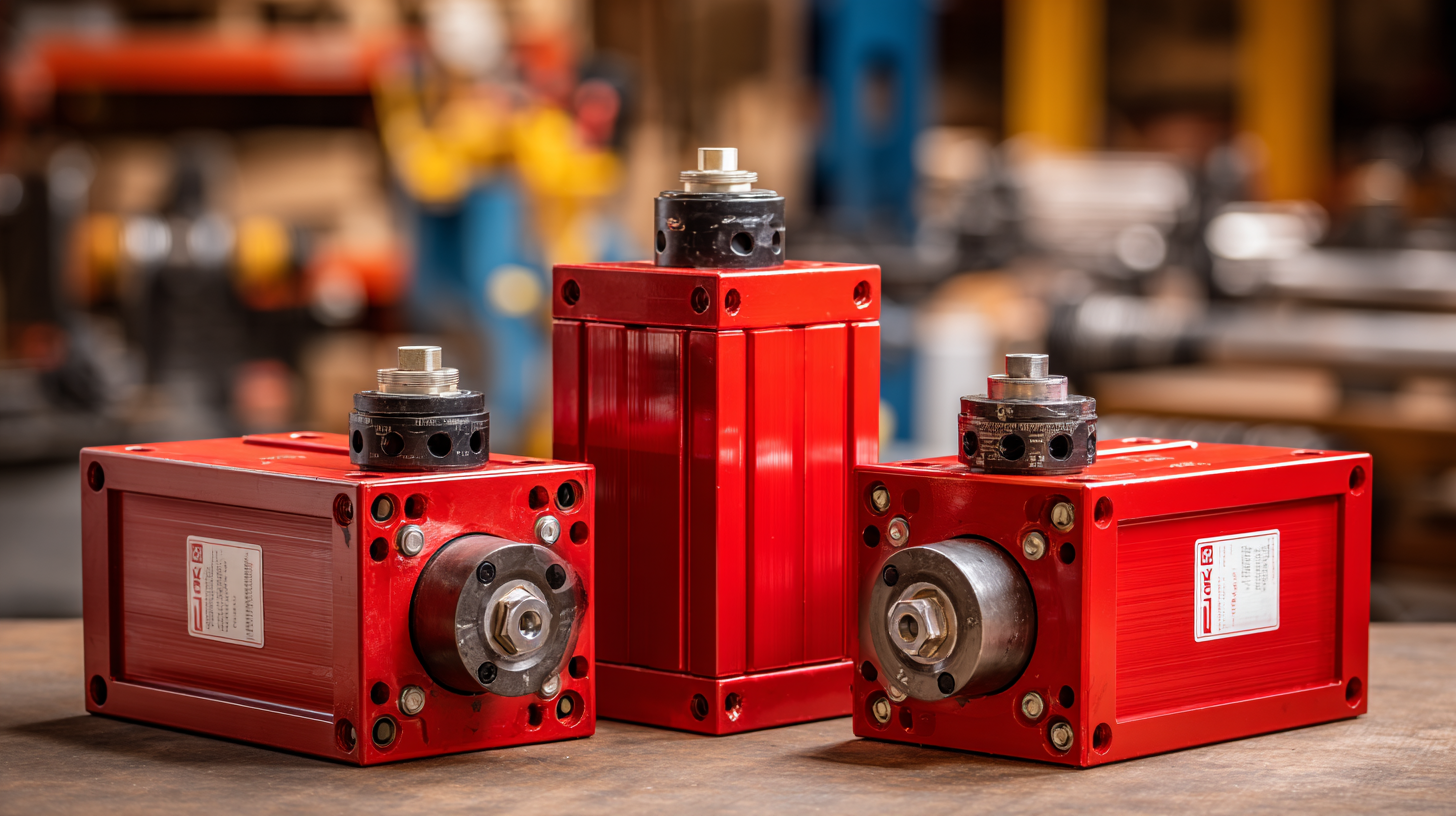

In the competitive landscape of industrial applications, the choice of components directly impacts efficiency and performance. Red Lion Cylinders, known for their durability and precision, have emerged as a preferred choice for manufacturers aiming to enhance their operational capabilities. A recent industry report revealed that implementing high-quality cylinder systems can improve production efficiency by up to 30%, underscoring the importance of selecting the right components for specific applications. With various factors such as load capacity, stroke length, and environmental conditions playing critical roles, understanding how to choose Red Lion Cylinders tailored to your operational needs is essential. This guide aims to illuminate the best practices for selecting the optimal Red Lion Cylinders to ensure not only improved performance but also increased reliability in demanding industrial environments.

When selecting the right Red Lion cylinders for industrial applications, it's essential to understand the various types available on the market. Red Lion offers a range of cylinder models, each designed for specific functions and environments. For instance, standard pneumatic cylinders are ideal for basic linear motion tasks, while double-acting cylinders provide a more versatile solution by allowing force application in both directions. In environments with limited space, compact cylinders can achieve optimal performance without compromising power.

Another key type to consider is the rodless cylinder, which is excellent for applications requiring high-speed and high-precision movement. These cylinders can fit within confined spaces and are often employed in automation processes. Moreover, maintenance and operational efficiency are significant factors; thus, choosing cylinders with easy-to-access service points will minimize downtime. Understanding these different cylinder types and their specific functionalities is crucial for ensuring optimal performance in various industrial applications.

This bar chart illustrates the performance characteristics of different types of Red Lion cylinders commonly used in industrial settings. The chart compares parameters such as Load Capacity, Stroke Length, and Operating Pressure for optimal performance selection.

When selecting the right Red Lion cylinders for industrial applications, several key performance metrics should be carefully considered to ensure optimal performance. First, evaluate the cylinder's material compatibility with the specific substances it will encounter during operation. Different materials can affect longevity and performance, especially under high pressure or extreme temperatures.

Another critical metric is the cylinder's pressure rating. Understanding the operational pressures within your application is essential, as using a cylinder that can't withstand these pressures can lead to failures or accidents. Additionally, examine the flow rate specifications to ensure that the cylinder meets the required output for your specific industrial processes. A mismatch in flow rates can lead to inefficiencies and hinder overall production goals.

Another critical metric is the cylinder's pressure rating. Understanding the operational pressures within your application is essential, as using a cylinder that can't withstand these pressures can lead to failures or accidents. Additionally, examine the flow rate specifications to ensure that the cylinder meets the required output for your specific industrial processes. A mismatch in flow rates can lead to inefficiencies and hinder overall production goals.

Finally, consider the installation and maintenance ease of the cylinders. User-friendly design features can significantly reduce downtime and operational costs. Accessibility for regular maintenance checks enhances reliability and safety in industrial environments. By focusing on these performance metrics, you can select the most suitable Red Lion cylinders, ultimately optimizing your operations and enhancing productivity.

When selecting the ideal Red Lion cylinders for industrial applications, understanding the environmental conditions in which these cylinders will operate is crucial. Factors such as temperature, humidity, and exposure to corrosive elements directly influence the performance and longevity of equipment. According to a report by the National Institute of Standards and Technology, up to 30% of hydraulic system failures can be attributed to improper cylinder selection influenced by environmental factors. Therefore, assessing these conditions rigorously is the first step towards optimizing cylinder selection.

When selecting the ideal Red Lion cylinders for industrial applications, understanding the environmental conditions in which these cylinders will operate is crucial. Factors such as temperature, humidity, and exposure to corrosive elements directly influence the performance and longevity of equipment. According to a report by the National Institute of Standards and Technology, up to 30% of hydraulic system failures can be attributed to improper cylinder selection influenced by environmental factors. Therefore, assessing these conditions rigorously is the first step towards optimizing cylinder selection.

Additionally, the compatibility of cylinder materials with the surrounding environment cannot be overlooked. For instance, a 2022 study published in the Journal of Industrial Engineering highlighted that cylinders exposed to high humidity environments require specialized coatings to prevent corrosion. Choosing materials like stainless steel or specialized composites can significantly enhance durability and performance in challenging conditions. By carefully evaluating these environmental aspects, operators can ensure they select Red Lion cylinders that not only meet operational demands but also thrive in their specific applications.

When selecting Red Lion cylinders for industrial applications, it's crucial to assess maintenance requirements to ensure optimal performance and longevity. Regular inspection and servicing of the cylinders can prevent common issues such as wear and tear or fluid leaks, which can significantly impact operational efficiency. Implementing a proactive maintenance schedule not only extends the lifespan of the cylinders but also reduces the risk of unexpected downtimes that can lead to costly interruptions in production.

Compatibility factors also play a key role in the selection process. Ensuring that the materials of the Red Lion cylinders are suitable for the specific industrial environment is essential, as this influences performance and durability. For instance, selecting cylinders that can withstand high temperatures or corrosive substances is vital in industries such as chemical processing or manufacturing. By carefully evaluating both maintenance and compatibility considerations, businesses can optimize the performance of Red Lion cylinders, ultimately contributing to a more efficient and reliable operation.

| Cylinder Type | Pressure Rating (psi) | Material | Temperature Range (°F) | Maintenance Frequency | Compatibility |

|---|---|---|---|---|---|

| Hydraulic Cylinder | 3000 | Steel | -20 to 180 | Annually | Oil-based Fluids |

| Pneumatic Cylinder | 150 psi | Aluminum | -4 to 160 | Semi-Annually | Compressed Air |

| Double-Acting Cylinder | 2500 | Stainless Steel | -40 to 200 | Quarterly | Water-based Fluids |

When evaluating Red Lion Cylinders for industrial applications, a cost-effectiveness analysis is crucial for budget-conscious operations.

According to a report by IndustryWeek, operational costs can account for over 70% of a company's total manufacturing expenses, emphasizing the need for efficient machinery that balances performance and affordability.

Red Lion Cylinders, known for their reliability and durability, often provide a longer lifespan than competitors, which can significantly reduce replacement and maintenance costs. Data from the National Institute of Standards and Technology (NIST) indicates that investing in quality components can lead to a 15-20% reduction in overall operational costs.

Furthermore, Red Lion's product range offers various configurations suited for specific industrial needs, allowing companies to choose cylinders that maximize efficiency. In a recent analysis by the American Society of Mechanical Engineers (ASME), systems designed with appropriately selected cylinders demonstrated up to a 30% increase in operational efficiency. This shows that selecting the right size and type of Red Lion Cylinder not only supports performance but also serves as a strategic move in cost management. By investing in quality and compatibility with existing systems, businesses can achieve both budget objectives and superior performance outcomes.